The making of articles, components or finished goods, also known as manufacturing, has been a skill that can date back to the Stone Age. Although a slightly different form of manufacturing, we still take those same concepts and apply them to our daily products.

Optimize creating your products with Autodesk Addictive and Subtractive Manufacturing

Check out our latest webinar on advanced manufacturing:

Subtractive Manufacturing

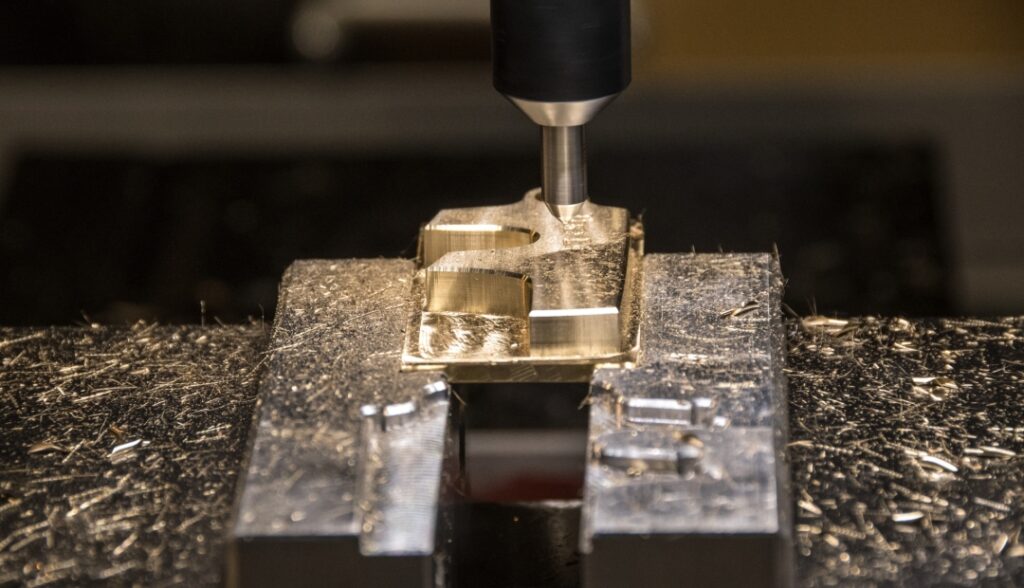

One of the most common and traditional forms of making a product is by means of using subtractive manufacturing. The concept is simple. You start with a raw block of material and start chipping away at it until you’ve finished with your final product. I like to use the analogy of a wood carver. The carver starts with a piece of wood and then starts slowly chipping at it until they get the shape or form they’re looking for.

In today’s world, however, things are a bit more complex. When referring to subtractive manufacturing, the term often refers to a process which involves a computer and some level of automation. CNC machines are one of the primary tools when using the subtractive manufacturing method.

The process usually involves a programmer giving the machine X,Y and Z coordinates. He then will have the machine cut or “chip” away at the stock until he finishes with the final part .

Additive Manufacturing

Additive manufacturing is a fairly new concept compared to its counterpart, subtractive manufacturing. Nonetheless, it is rapidly growing traction. Subtractive manufacturing has a few limitations when it comes to what you can build and where you can build it. Similar to subtractive manufacturing, additive manufacturing machines are also typically driven by X, Y and Z coordinates. However, instead of having the machine remove material, it builds the part up layer by layer often as thin as 20 microns for higher end machines.

The benefit of building up? There is no longer that uncertainty of crashing your $500,000 CNC machine while making intricate moves while trying to squeeze into every nook and cranny. Technology is advancing at a record pace and with designs. Like the one as below, being the norm for design concepts, manufacturing must be able to keep up and produce these unique parts one way or another.

In addition, additive manufacturing machines are much smaller in size than CNC machines. You can virtually take them anywhere and quickly have the ability to create prototypes anywhere in the world. One downfall, however, is build space. With smaller machines, the space allotted to build a part is limited, meaning parts must only be a few inches in order for you to create.

Combining Additive and Subtractive Manufacturing

Overall, you can combine the two methods in order to create high end functional components. While additive manufacturing, machines can build intricate shapes. However, surface finish tends to be on the rougher side, depending on the machine. A common workflow is combining both of these methods using Autodesk Advanced Manufacturing Toolsets. One of them is Powermill.

The software can program additive manufacturing machines to build the component from the ground up and then program CNC machines to chop away any tight tolerance features. If you would like to learn more about Autodesk’s manufacturing toolsets and how they fit into your business, don’t hesitate to reach out.

Take a look at the Autodesk advanced manufacturing products we offer at https://ketiv.com/software/advanced-manufacturing/