Aerospace Simulation Solutions

When failure costs millions and endangers lives, reliability is non-negotiable.

In aerospace, every decision matters—financially and physically. Hardware must withstand extreme conditions and meet strict performance and safety standards. But physical testing is costly and limited. Simulation enables faster validation, fewer redesigns, and better compliance from the start.

Unlock 25+ premium resources from Ansys and KETIV

Case studies from leading programs and manufacturers

White papers on propulsion, thermal, and electronics simulation

Expert insights on certification, autonomy, and mission modeling.

Build faster. Test smarter. Launch with confidence.

Access a curated library of 25+ high-value resources built for engineers and technical leaders working at the cutting edge of aerospace and space innovation.

Why Aerospace and Space Simulation?

Aerospace and Space simulation reduces development time and cost while ensuring safety and compliance with industry standards. Engineers can test different design configurations without building physical prototypes, saving cost and increasing productivity by identifying potential issues early. Simulation software enables precise modeling of aerodynamics, structural mechanics, and thermal management, which helps predict the behavior of aircraft, satellites, and spacecraft under real-world stresses. As digital twins and artificial intelligence integrate with simulation, traditional trial-and-error methods are replaced by more efficient, data-driven processes.

Cut Development Time & Cost

Simulation shortens the cycle of design, testing, and production by validating concepts early. Digital prototypes for wind tunnel tests, fuel cell efficiency assessments, or airflow analyses allow engineers to optimize geometries and material selections quickly. For example, computational fluid dynamics can predict how turbine blades respond to stress, reducing the need for multiple prototypes and lengthy physical tests. This accelerated approach supports leaner production cycles and lower overall R&D expenditure.

Guarantee Safety & Compliance

By simulating extreme conditions, aerospace teams can detect and mitigate design flaws that might compromise safety or violate regulatory standards. Analysis of high-velocity impacts or abnormal thermal variations ensures that critical components such as fuel tanks, landing gears, and engine parts perform reliably. Thermal simulation can predict how heat exchangers dissipate heat during prolonged operations, preventing failures. Regulatory agencies rely on verified simulation data as evidence that designs meet strict safety standards.

Real-World Success Stories

See how these industry disrupter shave accelerated development and slashed costs with simulation.

“Ansys guides users in how they want to set up and build models, and it guides them toward a best practice of modular, robust components that you then assemble into something else later. Just the way you use the program itself reinforces best practices in structural analysis and finite element analysis.”

Head of Structures at Whisper Aero

Built for Engineering Teams That Can’t Afford Surprises

KETIV helps companies design everything from hybrid-electric propulsion systems to space-based imaging platforms. We understand the pressures you face: long development cycles, limited physical testing opportunities, and a demand for total reliability in unforgiving environments.

Our work is grounded in real customer challenges. Whether it’s supporting a certification effort, accelerating early-stage design, or troubleshooting thermal margins, we bring deep expertise and what’s best for you to every engagement.

As an Ansys Elite Channel Partner, we help teams use Ansys simulation tools to:

- Predict how systems behave under thermal, structural, or vibrational stress

- Model electromagnetic interference to avoid mission-critical failure

- Validate electronics that must survive radiation and launch conditions

- Test and iterate propulsion and avionics designs virtually

- Prepare for FAA, EASA, and DoD certification with model-based approaches

- Simulate software and autonomy for safety-critical systems

Every decision in development has downstream consequences. Simulation helps you make better ones earlier—reducing risk while staying on schedule.

We Are Your Aerospace Simulation Partner

KETIV helps companies design everything from hybrid-electric propulsion systems to space-based imaging platforms. We understand the pressures you face—long development cycles, limited physical testing opportunities, and a demand for total reliability in unforgiving environments.

Our work is grounded in real customer challenges. Whether it’s supporting a certification effort, accelerating early-stage design, or troubleshooting thermal margins, we bring deep expertise and what’s best for you to every engagement.

The KETIV Simulation Team

Key Applications of Aerospace Simulation Software

Aerospace simulation software is integral in aircraft and spacecraft design, certification, and research. Its applications span aerodynamic performance analysis, guidance systems, propulsion, and structural testing, revolutionizing system conception and certification processes.

Aircraft Design and Aerodynamic Performance Analysis

Simulation enables the creation of detailed virtual models to study the interaction between aircraft and airflow. CFD tools simulate various flight conditions: subsonic, transonic, and supersonic to assess lift, drag, and stability. These insights inform design modifications such as wing shaping and fuselage streamlining to improve fuel efficiency and overall performance.

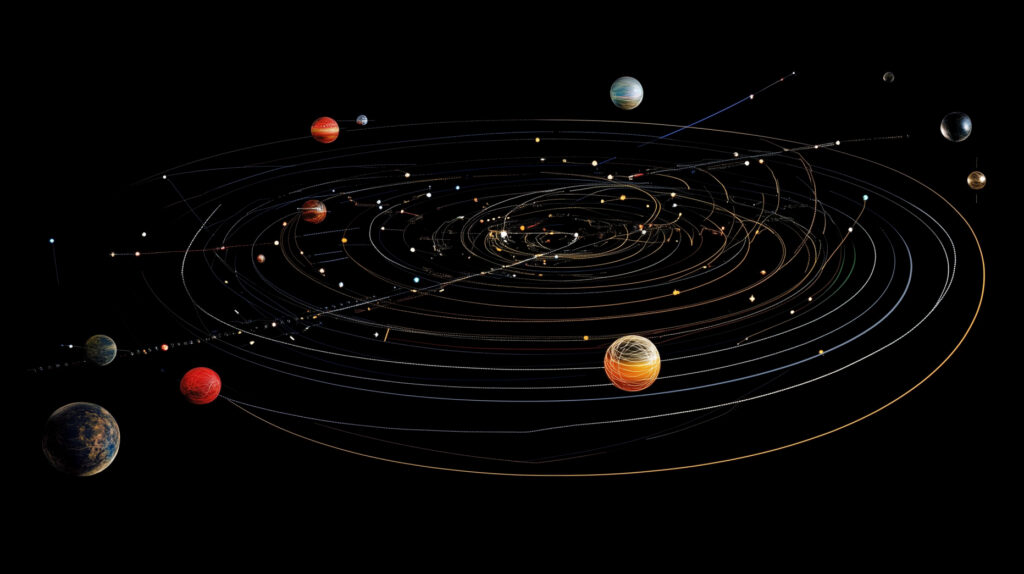

Spacecraft Trajectory Optimization and Mission Planning

For space missions, simulation tools predict spacecraft orbits, fuel requirements, and error margins. They allow planners to evaluate alternative trajectories and maneuvers, optimize docking sequences, and handle gravitational influences. This data-driven approach increases mission success while minimizing risk.

Propulsion System Development and Combustion Modeling

Simulation is essential for testing and developing propulsion systems. Engineers model combustion chambers, turbine blades, and nozzle designs in virtual environments. By simulating fluid flow, chemical reactions, and heat transfer in real time, these tools help optimize fuel-air mixtures, reduce emissions, and enhance engine performance.

Structural Integrity Assessment for Airframes and Space Structures

Aerospace structures are subjected to extreme stresses during flight and launch. Simulation tools using Finite Element Analysis (FEA) predict stress distribution, vibration responses, and thermal loads. This allows engineers to identify weaknesses, optimize material use, and reduce the need for extensive physical testing, thereby enhancing safety and reducing costs.

Simulating Guidance, Navigation, and Control Systems

Simulation of Guidance, Navigation, and Control (GNC) systems ensures that aircraft and spacecraft maintain accurate trajectories. By modeling sensor inputs, control algorithms, and environmental influences, simulation helps test the robustness of these systems. Integration with hardware-in-the-loop (HIL) testing further refines performance, ensuring safe and reliable operations.

Frequently Asked Questions

A: It minimizes design iterations, lowers costs, and ensures safety and compliance by replicating physical phenomena digitally.

A: They provide virtual prototyping and rapid iterative testing that help engineers identify flaws early, saving time and cost.

A: Digital twins offer real-time monitoring, predictive maintenance, and continuous performance optimization.

A: Yes, accurate simulation data supports certification processes by proving designs meet strict safety and performance standards.

A: It ensures that thermal, structural, and fluid dynamic analyses are conducted simultaneously, offering comprehensive system validation.