If you are considering using 3-dimension (3D) CAD software on your next design, you have come to the right place! There are several reasons to consider using a 3D CAD program such as Autodesk Inventor or Fusion 360 to develop your next design.

Visualizing in a 3D environment, determining physical properties, simulating, prototyping, machining, and generating accurate drawings are all compelling reasons to use 3D. Linked together, these reasons can form an entire design and engineering solution.

Why to use 3D CAD program

1) Visualize your design in a virtual 3D world

Designing in 3D gives you the ability to see potential issues in your design more readily, and address them earlier in the design process. Since the parts are created as 3D objects, instead of 2D views, potential interferences and trouble spots are easier to visualize.

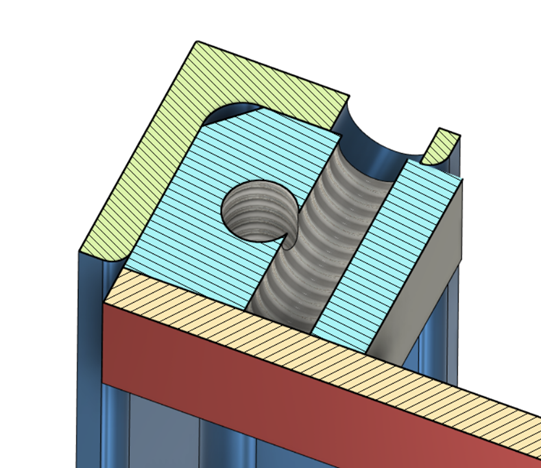

In the example below, a junction block joins two pieces of 90 degree angle. But a closer examination of the assembly shows that the threaded holes intersect each other. In short, the fasteners for this assembly will interfere with each other.

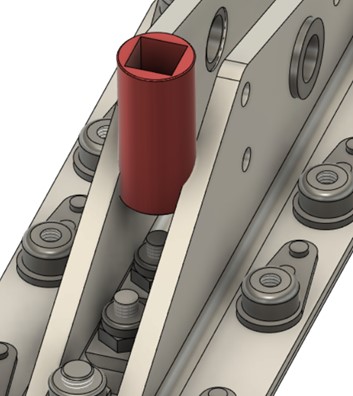

Speaking of fasteners, the designer can manipulate the fastener in a virtual assembly to ensure it can be inserted into place. A designer can even create models that represent tools. This can allow the designer to verify that once the fastener is in place, the tool required to reach and secure the fastener can be put in the proper position.

While it’s possible that some of these errors could be caught in a 2D program, as design complexity rises, it becomes more difficult. This is where 3D design tools provide the ability to validate the design, eliminate potential errors, and make for a more robust, efficient design.

2) Physical Properties are a Simple Task

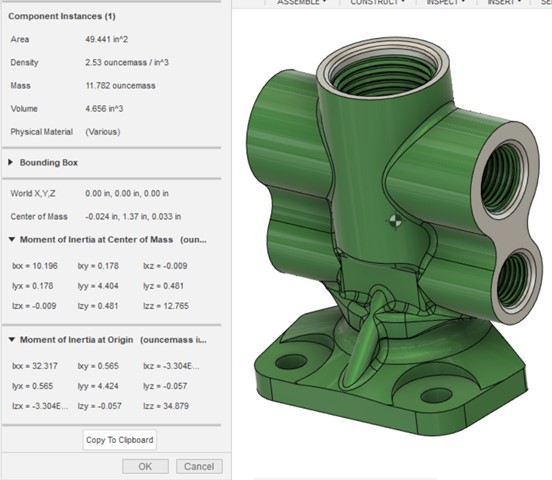

Physical properties such as volume, weight, center of gravity, and moments of inertia are often important to a design.

For example, weight and center of gravity is often critical data and a requirement in aerospace applications where weight and balance are involved. Perhaps the designer needs to calculate a shipping weight or confirm the product can be easily lifted by the end consumer. Whichever information the designer needs, a 3D tool can provide this data in a matter of seconds.

3) You’re One Step Closer to a Simulation, Prototypes, and Real Parts

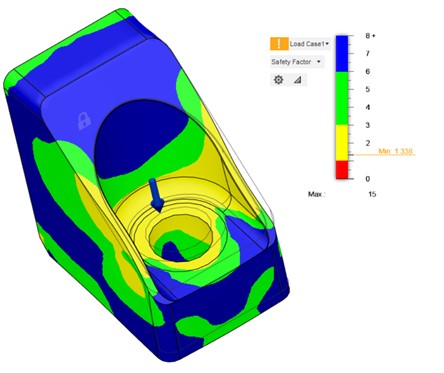

Another advantage of 3D models is the use of a digital prototype. The 3D CAD model can be transferred to Finite Element Analysis (FEA) programs for simulation or Computational Fluid Dynamics (CFD) programs for fluid flow and thermal analysis.

Your design can be tested and optimized virtually. 3D CAD tools allow the designer to balance the design for parameters such as weight, strength, and thermal properties. Dozens of design iterations can be tested before a physical model is ever created.

When the time comes to create initial physical examples, the 3D CAD model can be sent to a 3D printer for rapid prototyping. 3D printing can quickly create a physical prototype that can be reviewed by the design team.

The design can be evaluated for form, fit, and function with little time and inexpensively. This unique ability to transition a component from the virtual to physical world adds another opportunity to inspect and improve the design. Providing designers with another opportunity for optimization.

And when the time to machine the part arises, the model can be used in CAM tools such as Fusion 360 with FeatureCAM to create G-code for machining. This progresses the design to what could be the next prototyping stage, or it could even take the part into production.

These steps all begin from the initial 3D CAD model as it’s center. The analysis, prototyping, and machining tools can all use the 3D CAD model as their point of origin.

4) Drawings in 2D are Good, but 3D Makes Them Better

Even with this 3D technology, drawings still play a major role in the development of a design. And while newer tools such as 3D Annotation offer the promise to reduce the need for drawings, as it stands today, drawings are still needed. Drawings still provide a way to show critical dimensions and tolerances, as well as manufacturing instructions such as finish quality and lubrication points.

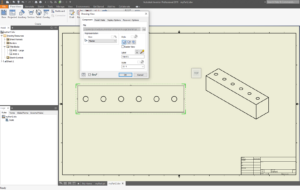

With a 3D model created, creating views is a matter of telling the drawing how to view the model. It’s like setting up cameras to look at a part from a given direction. As the model is updated, geometry and dimensions adapt to match the changes made in the model.

Another place that drawings still have a vital role to play is the Parts List, also called the Bill of Materials. As an assembly is created in 3D space, 3D CAD tools such as Inventor and Fusion 360 are counting the components and reading information such as description and material to populate the Parts List.

So, if the designer needs to check and see how many screws of a given material and size have been placed in the assembly, they only need reference the Parts List, and the information will be readily available.

And following the trend previously mentioned, if the assembly is updated, such as having a part added or removed, the 3D design and bill of materials will automatically update.

In Conclusion

By designing in 3D, you can create models that better conceptualize your design as it develops. These models can be used to obtain important physical properties, simulate for optimal performance, generate physical prototypes and production parts, as well as create drawings. These elements can be used whole or as part of an entire solution.

One of the best places to find that expanded knowledge is KETIV’s weekly Autodesk Virtual Academy, commonly known as AVA. Sign up here and start expanding your knowledge.