Ansys Motor-CAD | Electromechanical Design Software

Low Frequency EM Field Simulation

Ansys Motor-CAD streamlines electric machine design with dedicated tools for fast multiphysics simulation. Explore its capabilities across the full torque-speed operating range.

Fast Multiphysics Simulation for Optimal Motor Design

Ansys Motor-CAD enables design engineers to assess motor topologies and concepts comprehensively across the entire operating spectrum, ensuring designs are finely tuned for peak performance, efficiency, and size. By integrating four key modules—EMag, Therm, Lab, and Mech—Motor-CAD facilitates swift and iterative multiphysics calculations, expediting the journey from initial concept to finalized design.

- Intuitive, Template-Based Set Up

- Built-in EM, Thermal and Mechanical Solvers

- Full Operating Range Design

- Thermal Sizing of Machines

Ansys Motor-CAD Highlights

Ansys Motor-CAD users can now explore more motor technologies and fully assess the impact of advanced loss effects in the initial stages of electromechanical design.

What’s New

The 2025 R2 release boosts axial flux motor design accuracy with enhanced multi-slice equivalent linear modeling (ELM). The improved mechanical module assesses pre-stress and centrifugal forces early to ensure structural integrity, and the improved ratio-based modeling for wound rotor machines enables robust, geometry-aware design exploration.

Axial Flux Machine

Enhanced multi-slice support delivers significantly more accurate design capabilities for axial flux machines (AFMs). Building on the AFM template introduced in the previous release, which supports both single and dual topologies within the electromagnetic and lab modules, this advancement streamlines development and enhances design fidelity.

Pre-Stressed Mechanical Structure Integrity

The mechanical module now enables users to evaluate and compute the combination of pre-stress and centrifugal forces, providing critical insights into structural performance early in the design cycle. This capability empowers engineers to address the mechanical integrity of pre-tension due to rotor banding and press fit between shaft and rotor lamination, driving more robust and reliable product designs.

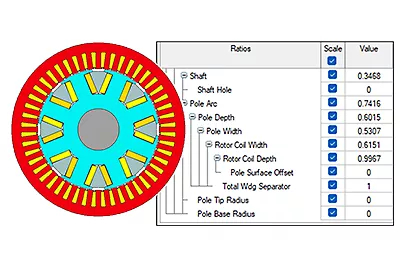

Ratio-Based Modeling for WRSM

Enhanced ratio-based modeling for wound rotor synchronous machines (WRSMs) enables robust geometric variation during design space exploration. This is crucial for large-scale parametric analyses and design studies, and it is a powerful tool for ensuring model robustness.

Capabilities

Integrated Multiphysics Analysis Software for Electric Motor Design

Motor designers now require tools that enable rapid decision-making without compromising on accuracy or efficiency. Ansys Motor-CAD’s integrated multi-physics analysis software simplifies the design process, empowering designers to explore diverse motor topologies and assess complex loss effects efficiently.

Motor-CAD software’s intuitive, template-based setup and embedded multi-physics expertise simplifies the design process and reduces reliance on multiple teams for specific electromagnetic, thermal, or mechanical experiences — so motor designers can keep more control over their designs.

Key Features

Ansys Motor-CAD delivers high-fidelity, 2D/3D analysis capability enabling users to analyze end-effects, demagnetization, core loss, hysteresis and other advanced electromagnetic phenomena, calculate the thermal envelope for operation and design complete motor cooling systems.

- Template-Based Electromagnetic and Thermal Design

- Electromagnetic-Thermal-Control Coupling Simulation

- Design for Field Weakening

- Temperature Dependent Continuous-Torque and Peak-Torque Simulation

- Manufacturing Effects and Housing Interfaces.

- Ratio-Based Optimization

- Magnetic Force Analysis

- Rotor Stress Analysis

Integrates with Ansys Maxwell and other physics solvers

Ansys Motor-CAD connects to Ansys Maxwell for advanced 2D and 3D electromagnetics analysis. For electric machine noise and vibration and (psycho-acoustic) sound prediction, Ansys Motor-CAD integrates with Mechanical and VRXPERIENCE. It also connects with Ansys CFD solvers and leverages air, water and oil based cooling techniques for cooling system design and analysis, as well as provides feedback into the Motor-CAD’s thermal model.

Template-Based Electromagnetic and Thermal Design

With Ansys Motor-CAD’s comprehensive geometry templates, users can explore the entire electric machine design space. These templates cover a wide range of technologies, topologies, and cooling systems, with new ratio-based parameterization options for enhanced design optimization.

Electromagnetic-Thermal-Control Coupling

Ansys Motor-CAD facilitates coupled multi-physics analysis from the outset, integrating control algorithms for virtual testing considering temperature effects over transient drive cycles or at steady state.

Design for Field Weakening

Designing modern electric machines requires performance analysis across the full torque/speed operating range. Ansys Motor-CAD enables designers to analyze field weakening behavior quickly and easily.

Temperature Dependent Continuous-Torque and Peak-Torque Simulation

Rapidly evaluate designs against the complete multi-physics performance requirements such as peak and continuous torque/speed characteristics.

Manufacturing Effects and Housing Interface

Ansys MotorCAD has built-in knowledge of manufacturing effects, guiding engineers in configuring manufacturing parameters appropriately. It enables straightforward sensitivity analysis to understand the impact of manufacturing variation on performance.

Ratio-Based Optimization

Ansys Motor-CAD is the ideal tool to use for optimization of electric machine designs. Powerful ratio-based optimization enables the design space to be explored easily while the coupled multi-physics analysis enables evaluation of each candidate design against the complete performance specification.

Magnetic Force Analysis

Ansys Motor-CAD automatically extracts and visualizes magnetic forces as a function of time and space, over the full operating range. Enabling NVH analysis of a design.

Rotor Stress Analysis

Rapid, automatic FEA based rotor stress analysis enables engineers to easily optimize rotor designs and trade-off between electromagnetic performance and mechanical constraints.

Ready to start working with Ansys Motor-CAD?

Resources

Thermal and Electrical Multiphysics Simulation: Modeling Joule Heating in Ansys

Electrothermal Mechanical Stress Reference Design Flow for Printed Circuit Boards and Electronic Packages

Get the asset

Get the asset