Thermal and Electrical Multi-Physics Simulation can be approached in many ways using Ansys simulation software. You can choose between different Ansys software components, as well as choose how to integrate them.

For instance, Joule heating can be approached in many ways within the Ansys platform. This blog will cover the benefits of using electrical thermal multi-physics with the ANSYS Electronic Desktop (AEDT) to do Joule heating, as well as the non-AEDT options that are available for use in the Ansys platform.

Electrical Thermal Multi-Physics

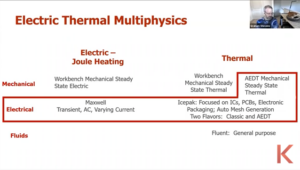

Within ANSYS mechanical products in Workbench you can use a Workbench Mechanical Steady State Electric analysis, as well as Mechanical Steady-State Thermal Analyses; and both combined can model joule heating.

Within ANSYS electronic product packages, Maxwell can be used to simulate a current moving through a device producing joule heating, and there are two different ways to model the system thermally. One is through Icepak, which is a full-featured solver within AEDT that has two different flavors, Classic and AEDT. The second is AEDT Mechanical steady-state thermal. It uses the same engine as the mechanical steady-state thermal within Workbench, but it is integrated into the AEDT platform.

Finally, there are the Fluids products, which also are used to model heat transfer and conduct thermal analysis. In general, one should start with whichever suite of products one is most familiar with; but be aware of some potential physics limitations. I assume for the rest of this post that you are an electronics product user – but the same considerations apply if you are more mechanically focused.

AEDT Mechanical or Icepak?

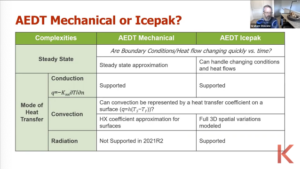

When getting started with the electronic desktop and using mechanical or Icepak to do the thermal analysis piece of Multiphysics, one must weigh the pros, cons, and limitations of each of the different packages. AEDT mechanical is slightly easier to set up and is faster, as it uses some approximations which allow you to run the calculations faster. Icepak is fully featured and can do anything you want when it comes to the thermal side.

When deciding between AEDT Mechanical and AEDT Icepak, one thing to think about is how the boundary conditions or the heat flow are changing over time. AEDT mechanical is much more appropriate for a steady-state approximation, where the electricity and or temperature conditions are not changing with time.

If the conditions change with time, then Icepak will be the right choice. If they are doing shock-like conditions where the current is changing quickly, even Icepak may not be able to handle that situation, in that case, you may need to slow down or change how you are modeling. Both packages can support conductive heat transfer, where heat is moving from a hot part to a colder part through conduction.

For convection, where there is air flowing or water cooling, and there is a flow field that is moving and transferring heat, there is a significant difference between the two packages. AEDT Mechanical makes an approximation that the whole flow field and the heat transfer associated with the flow field can be approximated by a heat transfer coefficient: (q=h(Ts – Tf)). This makes the resulting analysis accurately dependent on how accurate this assumption is.

If you know that you’ve got a full-featured flow and cannot approximate the full variability in space with a single heat transfer coefficient, then you will want to use Icepak to model the full 3D spatial variations. Icepack uses the same CFD engine as Fluent, so can support any type of heat transfer.

Finally, on the radiation side, at least up to version 2021 R2, AEDT Mechanical does not support radiation. If you know you have radiative transfer, you will want to use Icepak.

Should you use One-Way or Two-Way Analysis?

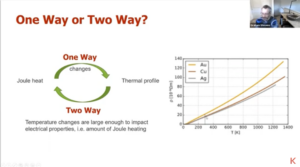

Another factor to consider is if you want to do one way or a two-way analysis. With Joule heating, when we put current through metal, and it heats up, you get a temperature change. That is a one-way analysis, where Joule heating provides the temperature, and we can find out what the temperature looks like with the one-way transfer.

If the heating then heats up the metal and changes the conductivity of the metal itself, then the temperature changes how efficiently the joule heating is occurring.

If you have a large temperature change compared to how quickly the thermal conductivity profile changes, then you want to use a two-way analysis to accurately change the conductivity, which then changes the temperature. If we cycle and do that a few times, we will converge and get a much more accurate answer.

The graph on the right shows the conductivity of copper, gold, and silver and how they change with temperature. If there is a small temperature change like 300K to 310K then the conductivity of the metal will not change much at all, and we can accurately use a one-way temperature change analysis. However, if this difference was 100 – 200K, then you may want to consider doing a two-way analysis for accuracy. Which way you go also depends on the level of accuracy needed for the analysis, too.

Now that you understand the benefits of each usage option within Ansys, please watch the full demonstration on Joule heating within AEDT from this Ansys Virtual Academy session.

You can also watch the Joule Heating in Mechanical Workbench webinar here.