Autodesk Inventor CAM

Connect Your 3D Models to Manufacturing Success

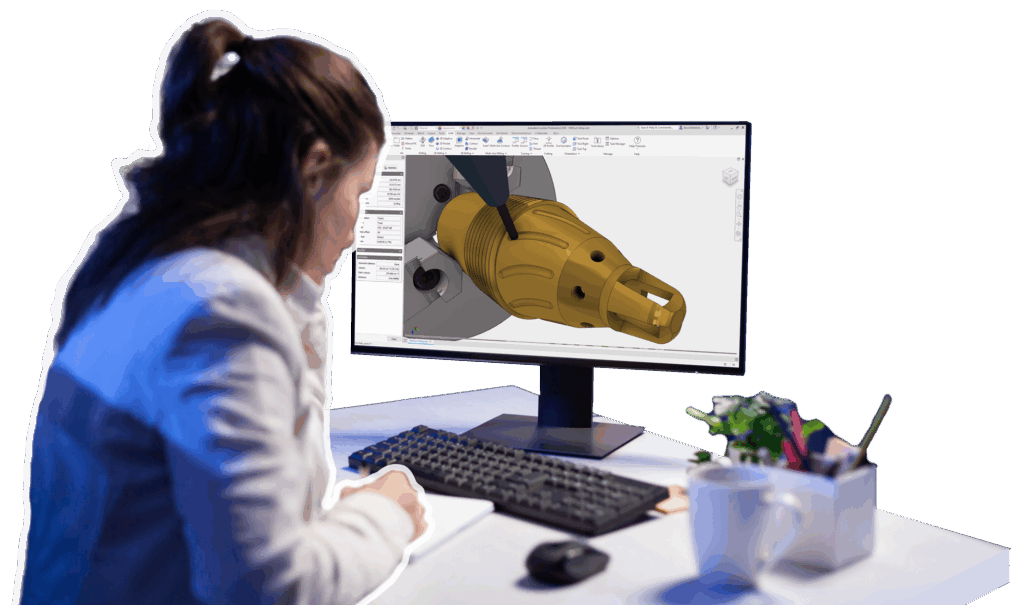

Design to Machining – Without the Disconnect

Autodesk Inventor CAM bridges the gap between engineering and manufacturing. Fully integrated inside Autodesk Inventor, it allows designers, machinists, and engineers to create precise toolpaths directly from a 3D model, eliminating file transfers and translation errors.

Whether you’re machining prototypes or running full-scale production, Inventor CAM simplifies CNC programming with intuitive tools that help you move from concept to finished part faster, reducing rework and maintaining complete alignment between design intent and manufactured output.

Why Manufacturers Choose Inventor CAM + KETIV

Companies using Autodesk Inventor CAM with KETIV achieve shorter setup times, higher part accuracy, and faster time-to-market. Because Inventor CAM runs within Inventor, every design update automatically refreshes the related toolpaths, keeping production in sync with engineering revisions.

With Autodesk Inventor CAM, you can:

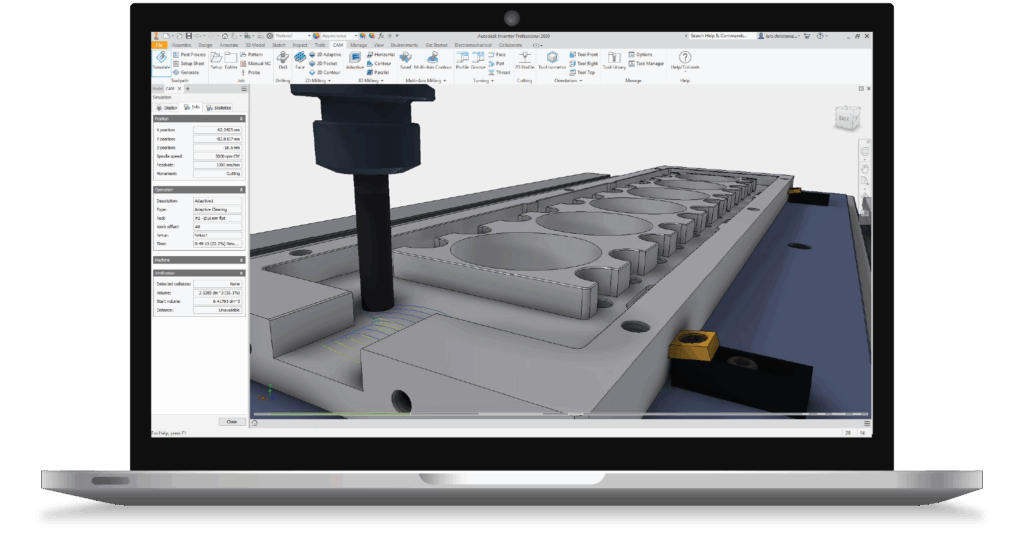

- Program CNC machines directly from your Inventor 3D model using intuitive CAM tools.

- Automate roughing, finishing, and multi-axis machining operations for faster production.

- Simulate toolpaths to verify accuracy and avoid costly errors before cutting material.

- Integrate seamlessly with Autodesk Fusion, AutoCAD, and the Autodesk Industry Cloud for collaboration and data management.

- Use adaptive machining strategies to extend tool life and maximize efficiency on every job.

Whether you’re prototyping a single component or running high-volume production, Inventor CAM delivers precision and control for modern manufacturing.

Key Features and Capabilities of Inventor CAM

Real-World Impact of Inventor CAM

Aerospace Example: Engineers create a parametric 3D model of a turbine component in Inventor, apply adaptive clearing in Inventor CAM, and export verified G-code directly to the shop floor, saving hours of setup and eliminating translation errors.

Automotive Example: Custom toolmakers model fixtures and generate multi-axis toolpaths inside Inventor CAM, automatically updating programs when engineers adjust tolerances.

Result: Shorter production cycles, fewer revisions, and a measurable ROI within the first quarter of adoption.

Why Partner with KETIV for Inventor CAM

KETIV is more than a software provider; we’re a manufacturing enablement partner. As an Autodesk Gold Partner, we help manufacturers deploy Inventor CAM successfully, train their teams, and optimize CNC workflows for maximum ROI. When you partner with KETIV, you gain a trusted guide to unlock the full power of Inventor CAM and achieve seamless design-to-manufacture integration.

- Customized implementation to connect Inventor CAM with your design and shop-floor processes.

- Training and educational access through the KETIV Virtual Academy to develop your team’s CAM expertise.

- Technical support and consulting for toolpath strategy, machine setup, and integration with other Autodesk tools.

- Continuous partnership that ensures your software and hardware work together for long-term productivity.