Why is stress simulation important? The simple answer is, it saves time and money. From startups to Fortune 500 companies, budgeting is always a primary concern. Unfortunately, having a high budget does not grant more room for errors to occur, thus making the interwoven concepts of time and money critical to any business.

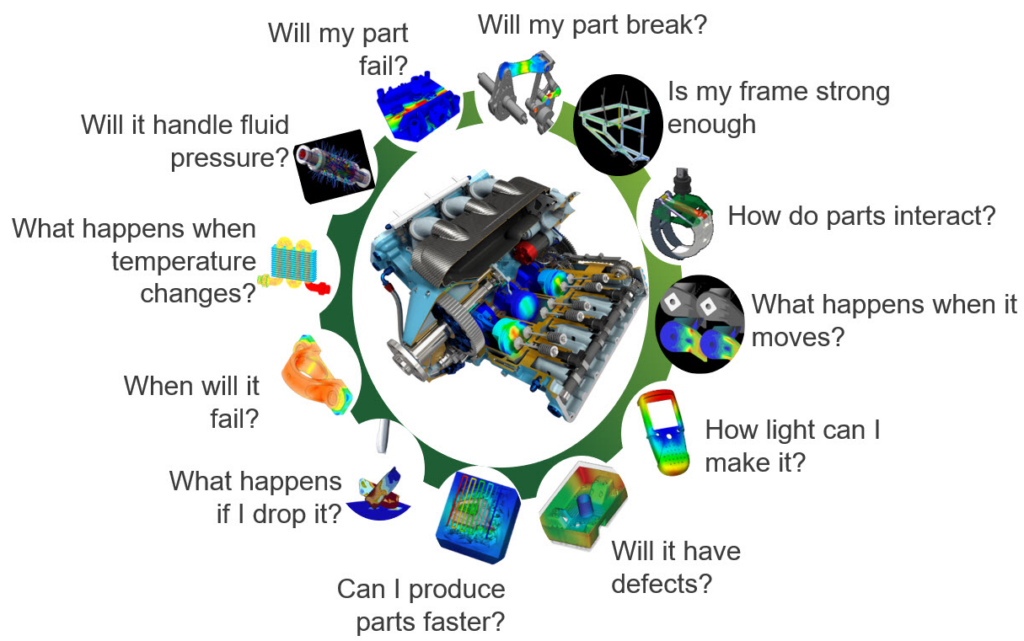

Luckily, simulation comes to the rescue by giving companies the power to speed up time to market, while minimizing part defects that are costly and a waste of material. Keep reading to learn more about the benefits of simulation.

How can simulation benefit you?

1. Time and Money

Let’s start with what we’ve already touched on. Initial designs may fail to meet requirements, but iterating virtually is far less time consuming and less costly. In fact, iterating the design with simulation is so efficient that the designer can afford to continue iterating. They can also do that even when a design has passed. They can search for a design that not only works, but also is of the highest quality and lowest cost. All of this can be done before the first physical prototype is even constructed.

With the help of simulation software, a company can verify and optimize designs, thus reducing verification and validation time cycle. This ability can cut down your design process from months to a few short days.

2. Innovation through Optimization

Simulation led design helps innovators design and test new concepts. It helps them comprehend the effects of physics and complicated equations at different conditions. The traditional method of testing would cost money, time and material, but even all this cannot guarantee accurate results since human errors are inevitable.

However, a company can optimize their designs by precisely calculated results through simulation. This is great news for research and development sectors.

The reason is that it helps create extreme real-life situations digitally and visualize complex processes and their behavior under varying conditions. Under these conditions, new innovations can take shape, and better products are the result.

3. Mitigating Hazardous Situations

Growing innovation and designing requires world class testing and validation to support it. For example, testing the stress forces on a car involved in a collision or even a small piece of metal under high stress and temperature recording can easily become a safety hazard. Even designs within electrical and magnetic companies become potentially dangerous to human life.

Opting for simulation avoids the risks of those potential dangers. How would you measure the strength of a material without breaking it or without a safety certification procedure? Simulation is the quickest and safest answer.

Simulation can be used in many contexts such as simulation of technology, safety engineering, performance and optimization, aerospace and mostly in places concerned with mechanics and fluids which KETIV’s Engineers are highly skilled in. It fits usually everywhere and in most stages of product engineering. It provides great value and helps optimize data right from the research stage to the end stage of validation and testing.

To sum up, investing in simulation will plant a seed for your successes tomorrow.

Register for Autodesk Virtual Academy, our free weekly training webinar, to keep learning about simulation:

[hubspot type=form portal=397692 id=6f2f5133-416d-4a02-a01b-379cfd5db119]