Product Lifecycle Management (PLM) and Product Data Management (PDM) are two terms that you may not hear too often. Chances are you are already following these processes in some way or form but just are not calling them PLM or PDM. If you create new products, manage suppliers, or track and approve changes, then you are already integrating Autodesk Vault PLM into your business. And if you are storing and managing your models, drawings, and related data during your engineering and design processes, then you are implementing PDM software in some form.

While each process is powerful and has its benefits on their own, connecting these two processes allows for information to be viewed and assessed in an efficient manner by the different departments of your company.

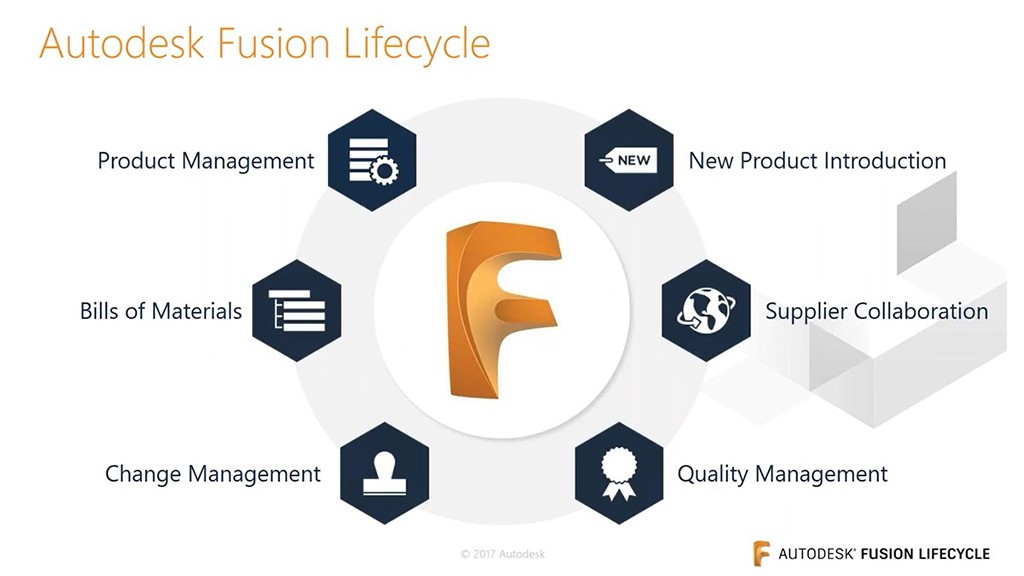

Product Lifecyle Management

As mentioned above, there are many stages to the PLM process. Those include New Product Introduction, Supplier management, Change Orders, and Items and BOM management. These are all pillars that are related to creating, marketing, and distributing your product, and each area has its set of people that oversee it. Fusion Lifecycle (FLC) is a tool provided by Autodesk. It allows these groups to interact with each other and oversee the processes as the products go through it.

While it brings these groups together to see the process, it can also separate the permissions each group has. FLC does this by creating multiple workspaces for each of the necessary functions, while these workspaces are separate in functions they are connected through their processes and next steps.

New Product Introduction – FLC

New Product Introduction is a process that typically requires input from many departments, including Engineering, Marketing, Suppliers and Manufacturing to name a few. FLC makes it possible to configure your workflow to match your process with the necessary milestones and tasks, giving you control over the deliverables and timeline that our customers require to bring products to market. Typically, a stage gate process is set up in this workspace that allows prerequisites to be met before moving to the next area of the product development process.

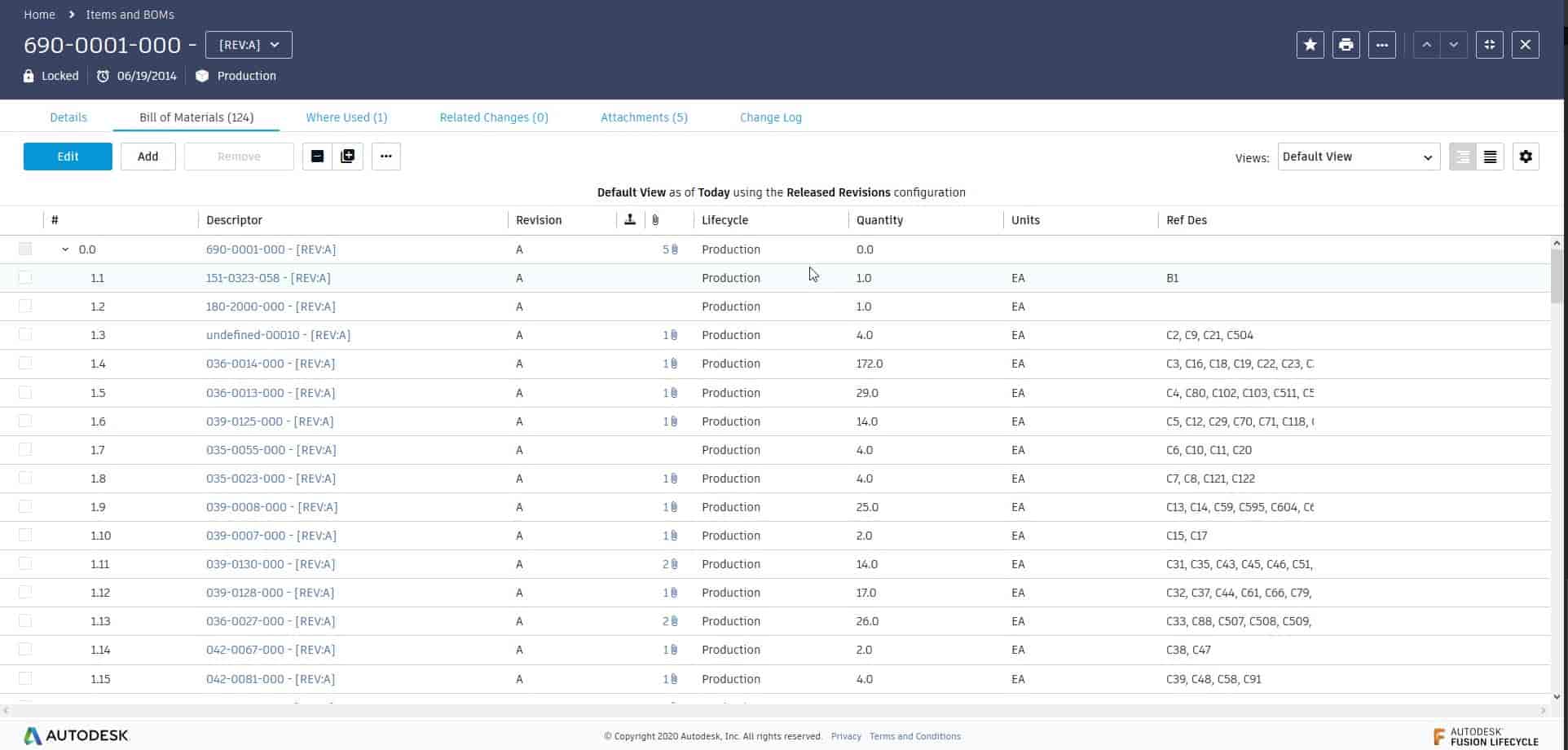

Bill of Materials – FLC

The Bill of Materials workspace in FLC allows customers to keep track of the structure of their product and list out the approved suppliers for each component. As mentioned above, the workspaces that are included in FLC all have their separate functions but are interconnected, one process leading to the next and to the next.

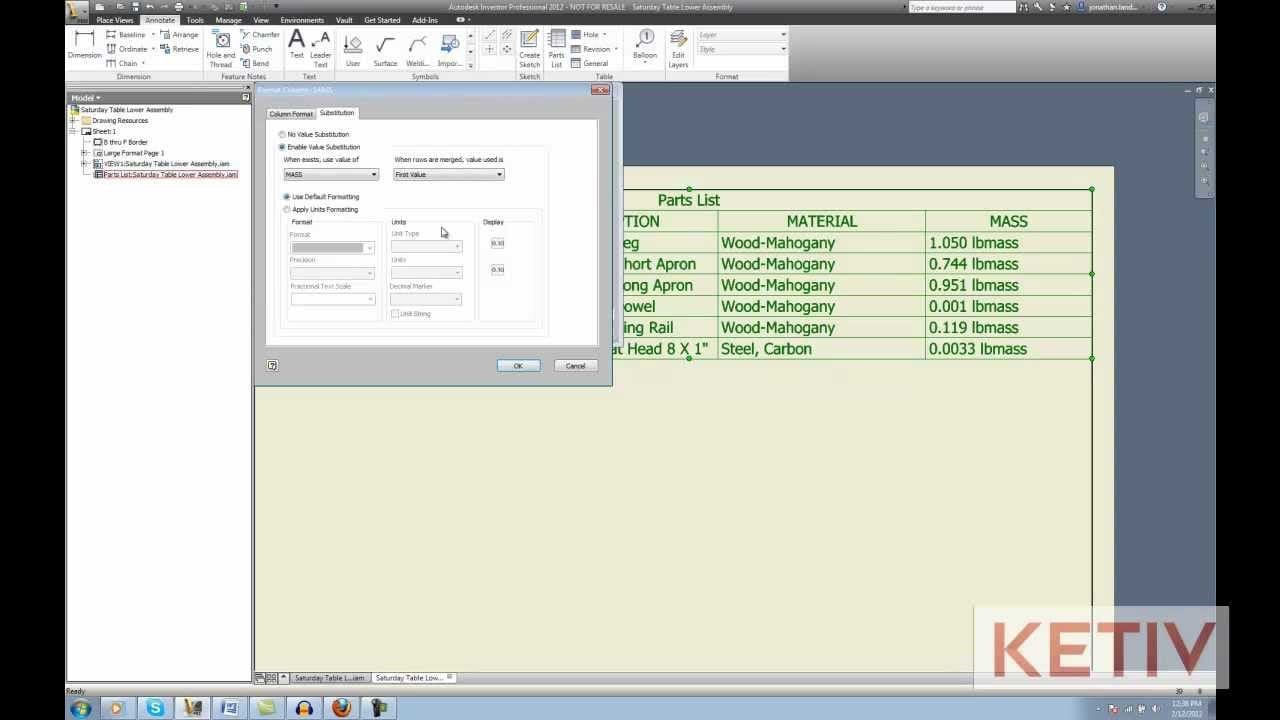

Product Data Management

At a certain point in the FLC process, there comes the need for the design and creation of the product. This brings in CAD data such as models and drawings, the BOM workspace allows us to see the structure and information about the product but the product itself is designed in Inventor or AutoCAD. Before this BOM is reviewed and approved in the PLM process, it must be viewed and approved in the engineering department.

Autodesk Vault allows customers to keep track of the files that are created for each product and ensure that the right people in the design process have access to them, typically this is done through lifecycles or BOM management with Items. It allows users to collaborate and generate the necessary files for design, which can then be shared back into the PLM process. These two tools working together are necessary due to the nature of the information that each tool handles. While Vault allows for the management of CAD files, FLC deals with information about the product in a broader sense.

Connecting FLC and Vault

While the information may exist in each tool separately, connecting them and sharing the information creates a stronger workflow and tool. Autodesk has worked with CoolOrange to create a connector that uploads and downloads information between FLC and Vault. The connector works to upload information about the BOM to FLC, ensuring that the BOM that is being viewed in FLC is up-to-date and accurate.

Another function that we see with this connector is managing changes that come from FLC. Changes can have different reasons for existing, such as customer requests, corrective and preventative actions or a redesign to fit a different market, but in the end the work will come down to the engineers to ensure that the changes are valid and meet the requirements. The mentioned connector improves this workflow by connecting the states of the files in Vault to the state of the item in FLC. If there is a request for a change that includes a certain part in FLC, the file can be unlocked in Vault to match the necessary state to make edits.

Get in Touch

Here at KETIV, we always want to make sure that everyone is aware of these tools and the capabilities that come with them, which is why we encourage you reach out to us and talk to us about how we can help you in your process. We know that in these times of change there are struggles that we must overcome and KETIV is dedicated in ensuring we all come out of this stronger together.

Please reach out to us with any questions you may have about Vault or Fusion Lifecycle and we will gladly answer them for you.