Introduction

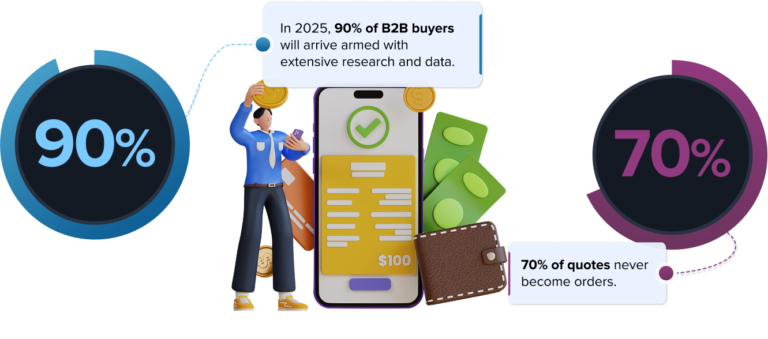

Modern manufacturing’s sales processes are undergoing a major shift due to evolving buyer expectations, particularly in engineering-centric workflows. In 2025, an estimated 90% of B2B buyers will arrive at sales conversations armed with thorough research, underscoring the need for adaptable strategies. Beyond simply improving products, manufacturers must focus on refining the buying experience across the awareness, consideration, and decision-making stages.

To succeed, they need to align sales operations and processes with buyers’ preference for independent research, while still offering expert guidance. Collaboration between sales and engineering teams is key to satisfying increasingly technical demands and earning long-term loyalty. Ultimately, leveraging technologies like AI and automation to create personalized, seamless interactions offers manufacturers a significant opportunity to thrive in a competitive landscape.

1. Well-Informed Buyers

Within B2B sales, manufacturing buyers are increasingly demanding greater autonomy and efficiency in their purchasing experiences, which is highlighting the need for manufacturers to adapt their strategies. We’ll have to simplify purchasing, engineering, and fulfillment to meet these expectations.

2. The Buyer’s Journey

Traditional sales tactics are increasingly ineffective, leading to longer deal cycles and smaller commitments. Understanding the buyer’s journey has become crucial for sales and marketing strategies. By effectively mapping this journey, companies gain invaluable insights into the evolving needs and pain points of their customers.

A. Awareness

Introduction to brand and gathering knowledge of your company and products.

B. Consideration

Researching specific products, options, and customer reviews.

C. Decision

Work independently, or with sales, to buy their tailored solution.

3. Autonomy vs. Expertise

Buyers prefer independent research yet expect expert guidance once they begin engaging with sales. Both present challenges to manufacturers who’ve yet to modernize purchasing processes.

AUTONOMY:

Self-Guided Buying

Modern buyers demand a personalized experience that caters to their unique needs, with a strong emphasis on convenience, quality, and transparency throughout the manufacturing sales process.

EXPERTISE:

Sales-Guided Buying

Sales people have long and tough training ramps, and a poor set of tools like antiquated catalogs, Excel files, and hand-made drawings to enable purchase decisions with customers.

4. Sales and Engineering Collaboration

Streamlined sales-to-engineering workflows are critical to meet technical buyer demands.

SALES TEAM

Product Configuration

Sales engineers are expected to facilitate product demos and translate complex technical jargon into easily digestible information for both sales teams and clients, which helps in streamlining sales cycles.

ENGINEERING TEAM

Quotes, CAD, and BOM

Engineering teams are tasked with keep up with the demands of sales team estimates, as well as validating customer orders and pricing, engineering custom solutions, generating BOMs to initiate production.

5. Technology and Automation

It’s time to leverage advanced technologies, such as AI, automation, and CPQ (Configure, Price and Quote) to re-think the manufacturing sales cycle. These tools can foster personalized, responsive buying experiences that resonate with modern buyers!

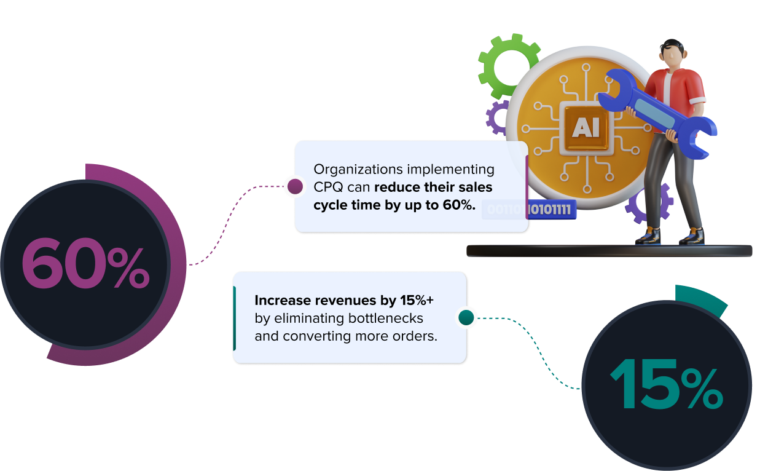

THE POWER OF CPQ

Technology and Automation Applied to the Sales Process

Configure

Product configuration is guided by your engineering rules to ensure only manufacturable features are presented to each buyer, accelerating the sales cycle and minimizing errors and conflicts.

Price

Guided by real-time data, dynamic pricing ensures accurate cost calculations are presented immediately to the buyer. Drive deal transparency while safeguarding your profit margins.

Quote

Generate an accurate proposal including all product configurations and pricing details. Include visuals, stock availability from ERP systems, and clear terms to ensure buyers finalize quickly.

6. Visualization and VR/AR

Manufacturing companies can take configuration further with advanced tools like 3D visualization and augmented reality. This allows customers to see how their configured products would look in real-world environments, making the experience both engaging and decisive.

7. Connected and Integrated Manufacturing

When you have this level of upfront order configuration data, and can integrate that data thread with the rest of your systems and processes, you unlock a power workflow to drive the shop floor from the sales process.

INTEGRATED SYSTEMS & PROCESSES

Constructing a Data Thread

Proper CPQ systems allow manufacturers to connect pricing systems, ERP, CRM, and other key system to power configuration and guard customers and sales people from supply chain disruptions.

PRODUCTION OPTIMIZATION

From Purchase to Production

Manufacturing CPQ solutions need to auto-generate drawings for quotes and production, and should push detailed BOM, assembly, and other order fulfillment information directly to fabrication teams.

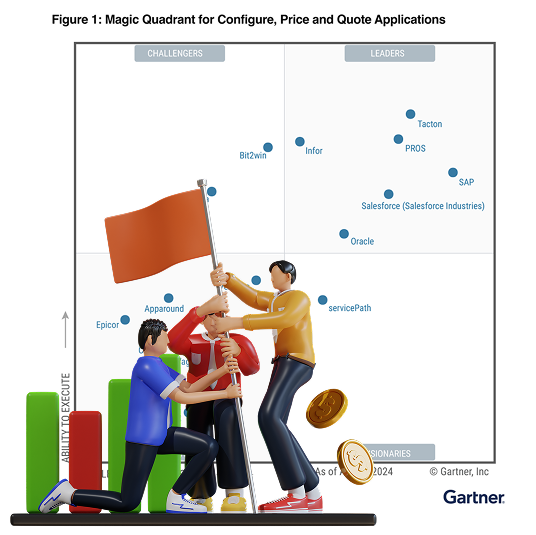

Why Tacton CPQ + KETIV

KETIV partners with Tacton, the fastest-growing configuration, price, and quote (CPQ) solution for manufacturers worldwide, in order to power our customers’ most complex product and pricing solutions.

From visual configuration to CAD automation, KETIV recognizes Tacton CPQ software as the spearhead to enact end-to-end automation for manufacturing companies.

A THREE-TIME LEADER IN CPQ APPLICATIONS