Common Challenges with Shared Drives for PDM

Managing CAD files and engineering data on shared drives—whether it’s a network folder or a cloud-based solution like OneDrive, Box, or SharePoint—can introduce multiple risks that directly impact your productivity and bottom line. Below are some of the most common pitfalls design teams encounter when relying on shared folders for PDM.

File/Folder Confusion and Broken Links

One of the most frequent pain points with shared drives is the ease of moving entire folders—sometimes by a simple click-and-drag—without realizing the broader impact. When a folder or file is moved, renamed, or deleted:

- Broken References in Assemblies: Complex CAD models and assemblies rely on file references being in the right place. If even one component is moved to a different folder, the top-level assembly will prompt for missing files or fail to open entirely.

- Time-Consuming Searches: Suddenly, team members are left hunting for files across multiple directories, often with vague or inconsistent naming conventions. Productivity slows while everyone tries to locate and relink assets.

- Unintentional Data Loss: Without version history or an audit trail, it’s hard to recover when entire folders go missing. Even if backups exist, restoring data can be cumbersome and disruptive to project timelines.

No Granular Security

In many shared-drive environments, a single set of permissions is often applied to a top-level directory, inherited by all subfolders. This lack of nuanced access control creates a range of security and workflow issues:

- Excessive Access Rights: Any user with permission to “write” or “delete” files can modify or remove critical design data—even if they’re a new hire or part of an unrelated department.

- No Traceability: When something gets overwritten or deleted, there’s usually no record of who did it or when. This makes it difficult to hold team members accountable or to implement proactive safeguards.

- Sensitive Data Exposure: Engineering documents often contain proprietary information. In a shared-drive setting, there’s little to stop someone from copying or sharing files externally without detection.

Synchronization Delays

Cloud-based drives like OneDrive or Google Drive offer convenience, but they’re not designed for the high-frequency edits and large file sizes typical in CAD environments:

- Slow Assembly Load Times: Large assemblies may take significantly longer to open if they’re not fully synced locally. Designers end up waiting while files trickle down from the cloud.

- Rework from Version Conflicts: If team members open the same file before it’s updated to the latest version, they might unwittingly make changes based on outdated data. That can lead to rework and inconsistent designs.

Data Duplication

A surprising yet frequent challenge is the inadvertent creation of multiple identical files:

- Unnecessarily Recreated Parts: Without a robust search function, engineers often can’t find existing designs—say, a standard bolt—so they model a new one. Over time, you end up with 10 different “Bolt_1” files, all slightly different in name but physically the same part.

- Inconsistent Naming Conventions: Shared drives rarely enforce naming rules. When the same item is saved as “Bolt,” “Bolt_final,” or “Bolt_CompanyX,” you end up with a patchwork of data that’s nearly impossible to track.

- Higher Purchasing Costs: Repeated parts inflate inventory orders. Purchasing teams may place separate orders for parts that are functionally identical because they appear as unique items.

What Should PDM (Product Data Management) Do?

Version History and Control

A solid PDM solution automatically captures every version of a file, keeping a complete record of who made changes and when. This ensures you never have to guess which version is the latest or scramble to figure out who modified a model before sending it to production. By maintaining a clear “check in/check out” process, PDM systems also prevent accidental overwrites—only one user at a time can have the file in an editable state. Once the design is checked back in, the system creates a new version, allowing you to restore any previous iteration if needed.

Edit Control and Permissions

PDM platforms let administrators set specific roles and privileges, dictating which users can view, edit, or approve certain files. This level of control is critical for safeguarding sensitive designs and proprietary information. It also helps avoid the confusion of multiple people simultaneously editing the same file. For instance, if a senior engineer is making final tweaks to a critical assembly, the PDM system can lock out others from making conflicting edits until the file is safely checked back in.

Workflow Management

Many design projects involve multiple stages of review and approval before moving into manufacturing. A well-configured PDM tool streamlines this process by enforcing structured workflows. Teams can define clear approval gates—such as “In Review” or “Released”—ensuring that only validated designs progress to the shop floor. This workflow control reduces the risk of unfinished or erroneous CAD models getting manufactured prematurely. Moreover, it keeps collaboration efficient and organized by tracking where each file is in the process, replacing ad-hoc folder structures and email chains with a centralized source of truth.

Data Integrity and Audits

In an ideal scenario, every change to your product data is documented—who made it, why it was made, and when. PDM systems capture this information automatically, providing an easy way to perform root cause analysis if problems arise later in production or in-field performance. This visibility helps you catch design errors faster and reduces the chance of repeating the same mistakes. Additionally, having a complete audit trail simplifies compliance with industry regulations and standards that may require strict documentation and proof of quality controls.

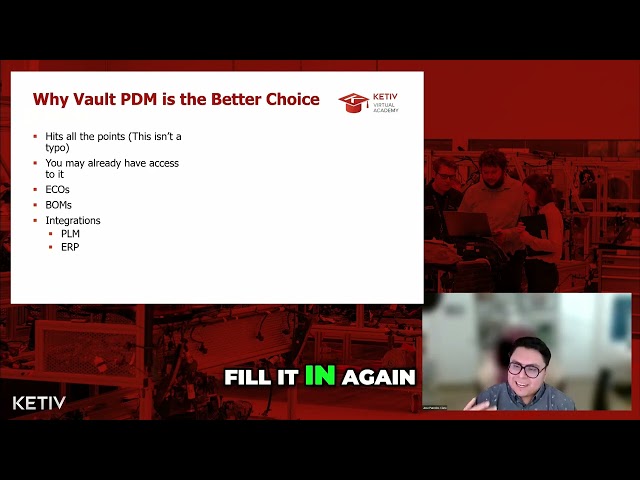

Why Autodesk Vault PDM Is A Strong Choice

Comprehensive Version History and Accountability

Vault automatically captures the full history of changes—who edited a file and when—ensuring every revision is traceable. This not only prevents files from being accidentally overwritten but also provides a clear audit trail. You always know the “who, what, and when” behind each design tweak, which greatly simplifies troubleshooting and fosters accountability among team members.

Robust Security and Permissions

Unlike shared drives, Vault offers granular control over who can view, edit, or release specific files. Administrators can group users by department or role (e.g., new hires, senior engineers, production staff), tailoring permissions to each group’s needs. This structure reduces the risk of unauthorized edits, accidental deletions, or inappropriate access to sensitive data.

Workflow and Lifecycle Management

Vault’s lifecycle management features help ensure that designs move through a predefined sequence of states—such as “In Progress,” “For Review,” and “Released.” This structured process eliminates the chaos of ad-hoc folder structures or email sign-offs. It also keeps incomplete work out of manufacturing, reducing mistakes and costly rework. Plus, Vault Professional adds change orders (ECOs), allowing specific teams to be notified and assigned tasks at the right time.

Integration with Inventor, PLM, and ERP

Vault is tightly integrated with Autodesk Inventor, meaning design data automatically syncs with the PDM system. If you’re using Vault Professional, you can also link to ERP or PLM platforms—removing the need for manual data entry in multiple systems. When designers update part numbers or Bill of Materials (BOM) information in Inventor, that information can flow seamlessly to downstream systems, minimizing human error and improving overall data accuracy.

Additional Features with Vault Professional

While Vault Basic provides many advantages out of the box, Vault Professional expands your capabilities further. It offers advanced change order workflows, item management, and enhanced BOM functionality. These features help you organize large assemblies, manage product families, and maintain a single source of truth for critical product data—ideal for companies looking to scale their design and manufacturing processes efficiently.

Resources & Next Steps

Autodesk Vault Maintenance Tips

4 Tips to Maintaining a Healthy Autodesk Vault

This quick and handy guide is great to have on hand if you are responsible for maintaining a healthy Autodesk Vault instance. KETIV’s top experts have documented four key tips to ensure things run smoothly from Database to Filestore, and beyond. They even threw in a bonus tip for SQL Express users out there.