Overview

Create more robust multibody dynamic system designs

Ansys Motion is a fully integrated simulation tool for modeling components and systems. It gives fast and precise analysis for both rigid and flexible bodies using a single solver. System motion performance, stress-safety analysis, heat transfer, vibration, and fatigue are all part of its capabilities. Ansys Motion is the top simulation solution for designing multibody dynamic systems.

Product Specs

You can perform simulations in Ansys Motion using the same interface as your regular structural analysis. Save time by reusing a single model for various purposes. The specs include the Ansys Motion Links modeler for tracked vehicles, FE Dynamics tools, and more.

What's New

2024 R1 release of Ansys Motion

Drivetrain Enhancements

New drivetrain enhancements now include Tooth Contact Pressure (TCP) and Deformation (TCD) calculations. They also offer a method to calculate tooth stiffness and a “tolerance” tab for gear specifications. These updates give users a more precise and realistic analysis of gear performance and durability.

Updated Python Module

With the Python module, users can now define motion, force magnitude, and other complex outputs. This allows them to automate tasks and improve efficiency.

Guide Messages

Users can now troubleshoot solver errors with new user-friendly guide messages. This saves them time and reduces frustration when solving complex problems.

Capabilities

Ansys Motion is a pioneering force in flexible Multibody Dynamics (MBD).

Ansys Motion allows for fast and accurate analysis of rigid and flexible bodies within a single solver system. Motion reduces time-to-market by performing system motion performance, stress safety, vibration, and fatigue analysis during the design process across many industries. Motion’s integrated GUI offers a strong modeling environment for components and systems, which can be analyzed independently or simultaneously, opening new possibilities during design and analysis.

Key Features

- Solver

- Pre-post Processor

- MBD Pro

- FE Dynamics

- Modal Flex

- Linear

- Fatigue

- MATLAB Interface

- FMI

- Drivetrain Toolkit

- Links Toolkit for Chains and Belts

- Links Toolkit for Tracks

- Car Toolkit

- Easyflex Toolkit

- CAD Translators

Solver

The Motion solver can speed up simulations for systems with a large degree of freedom. It uses shared memory parallel processing (SMP) and massive parallel processing (MPP) environments to simulate faster.

Pre-post Processor

Optimize modeling environment for components and systems with Ansys Motion's pre-processor. Model components as a single entity with a part file and a mesh file. Part and mesh files are managed independently, allowing for data reuse in other models. The post-processor provides fast animation of systems with complex geometries.

MBD Pro

MBD Pro is included in the Ansys Motion base package and analyzes rigid body systems. It uses parametric generalized coordinate systems to formulate the governing equations of motion. Rigid bodies are connected by joints, primitive constraints, bushings, contacts, and user-defined functions. Smooth surface-to-surface contact is supported, with surfaces represented by piecewise triangular patches or NURBS surfaces.

FE Dynamics

Perform dynamic analysis on a mixed system of rigid and flexible bodies. The solver combines the disciplines of multibody dynamics (MBD) and finite element (FE) analysis. It includes many unique connecting elements for rigid and flexible bodies. Using a numerically stable implicit integration method, the solution is smooth, reliable, and free from numerical noise.

Modal Flex

For a flexible body with no contact or only slightly changing force elements, the modal flexible body is preferred for its efficiency. Mode shapes are extracted from a finite element program like Ansys Mechanical, and deformation is expressed as a linear combination of these mode shapes. This method solves reduced modal coordinates, making computation time shorter. You can easily switch between modal flexible bodies and full nodal flexible bodies, and solve them alongside other rigid and nodal flexible bodies.

Linear

Linear analysis is used to solve eigenvalues and eigenvectors for FE bodies, EasyFlex bodies, or systems. It can simulate natural frequencies and modes. For more accurate results in body eigenvalue analysis, the static correction mode is recommended for modal flexible bodies.

Fatigue

Traditional fatigue analysis required separate analyses for load history and stresses. In Ansys Motion, these processes are combined into one system. The Ansys Motion solver generates both load history and stress history simultaneously. You can directly view the fatigue life in the Ansys Motion post-processor.

MATLAB Interface

Included in the Ansys Motion base package, the MATLAB/Simulink interface enables co-simulation between MATLAB control models and Ansys Motion mechanical models. You need to define system input/output in the Ansys Motion model and in the Simulink file in MATLAB.

FMI

The functional mockup interface (FMI) capability allows Ansys Motion mechanical models to co-simulate with other simulation tools that support FMI. You must define the system input/output in the Ansys Motion model. Note that Ansys Motion’s FMI is available only as a slave simulator.

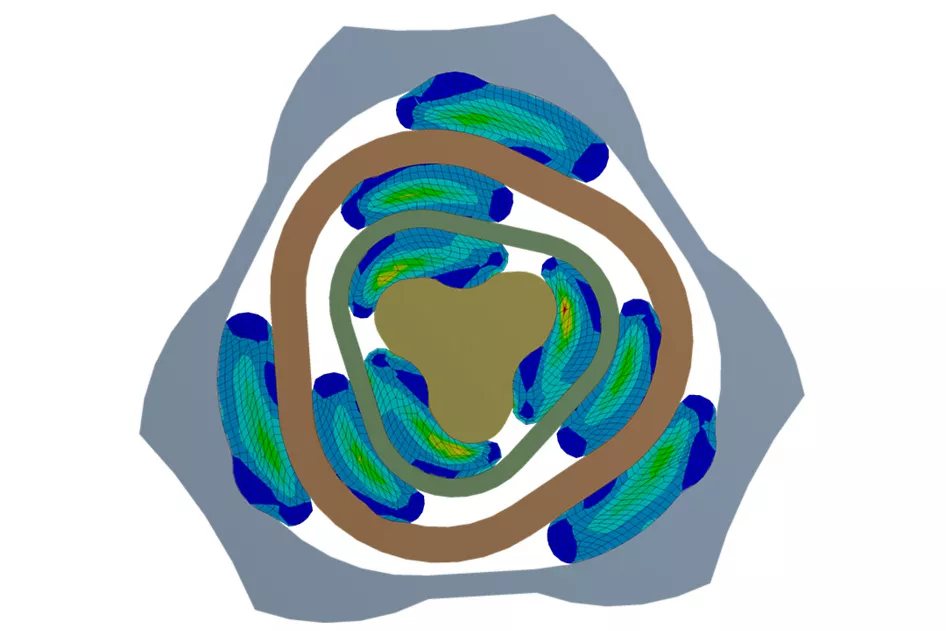

Drivetrain Toolkit

It can conduct analyses from the initial design concept through to detailed production models. Waterfall color maps and order tracking data can be produced in the same manner as in a real-world test environment to allow easy comparison of simulation and reality.

Links Toolkit for Chains and Belts

An Ansys Motion Links toolkit analysis involves path bodies (wound bodies) and segment bodies (winding bodies). Once you define these bodies, a chain assembly is automatically created. Path and segment bodies can be subsystems, parts, or mesh files, allowing you to build various types of irregular chains. All contact parameters among the segment and path bodies are controlled from one window. Connections between segments can include any type of force, joint, or contact entity.

Links Toolkit for Tracks

Predefined geometries for segment and path bodies are provided, enabling parametric studies. Track assembly is further simplified by eliminating the need for manual selection of path bodies. The path bodies are automatically identified and used to assemble the track segments. Contact surfaces are predefined for these geometries, so there's no need to manually define them. These predefined geometries include intricate modeling details to accurately represent real shapes.

Car Toolkit

Dedicated template and subsystem modeling tools can be utilized to construct chassis, suspension, steering, and wheels for predefined analysis scenarios. Symmetric modeling capabilities and template-based workflows enable users to effortlessly analyze kinematics and compliance (K&C) as well as ride and handling (R&H) scenarios.

EasyFlex Toolkit

Unlike traditional finite element analysis, the Ansys Motion EasyFlex toolkit eliminates the need for meshing prior to structural analysis. This makes flexibility modeling accessible to all users, even those without experience in meshing technologies. By utilizing the Ansys Motion EasyFlex toolkit, strain and stress calculations for machine parts of various shapes can be completed within minutes.

Translators

The Ansys Motion pre-processor is built on the ACIS kernel, allowing direct reading of .sat and .sab files. Other CAD data files need to be translated using the appropriate CAD translator.