Addressing common questions

I’ve been working in the stress simulation industry for a few years now and this is a question that I’ve been asked rather frequently. Although I’ve been told it’s not good to answer a question with another question, sometimes it’s necessary.

Before I answer that question, I would ask: “With respect to what? With respect to input data? Real life of the product? Test data? Regulation standard? Or perhaps QA measure?” What;s more, there are so many questions I could keep asking. They all are valid questions to respond to the original question if you ask me.

What’s more, I also have come across: “Did I make any mistakes in my study?” This is the same general idea but slightly different flavor. The answer to this question would be: “I might be able to find some mistakes but only you (as you the engineer) are in a position to catch them all.” There are some cases where users make mistakes by applying twice the load or perhaps the mistake is in the material’s properties, thickness, etc. How can someone external know if it’s right or wrong?

A linear analysis

Sometimes, the question of accuracy is not based on the methodologies or program implementation and capabilities, but on a particular problem in mind. This is great. However, you need to make sure that the type of stress simulation you run corresponds to the mode of failure you are observe or expect in reality.

A linear analysis is only good as long as the underlying linearity assumptions are satisfied. A static simulation analyzing strength does not reveal much about a fatigue failure. It analyzes life under cyclic loading. If you do not know which failure mode you have to pursue, you have 2 option. You should either simulate all different modes of failure or do some experiments in the lab to gain a better understanding of which failure modes to rule in or out.

If you ask someone: “Are there any mistakes?” only you, the engineer, know what type of failure you are solving for. Perhaps only you know what the correct boundary conditions and valid assumptions are that we could make.

Fundamental concepts for linear static analysis

There are also fundamental concepts that you need to understand in order to get accurate results. I think what people often forget when they are performing a linear static analysis, is that when they go beyond material yield strength anywhere in the design, a re-distribution of stress will occur which can only be captured by a nonlinear analysis. Let’s remember that linear static analysis assumes that the relationship between loads and the induced response is linear. Meaning, if you double the magnitude of loads, the response will also double. The response includes displacements, strains, stresses, reaction forces, etc.

However, nonlinear analysis do not behave in this manner. In the real world most of the structures behave non-linearly in one way or another at some level of loading. Linear analysis may be adequate, as long as you understand the assumptions and the materials do not go over the yield strength. In many other cases, the linear solution can produce erroneous results because the assumptions upon which it is based are violated.

Non-linearity can be caused by the material behavior, large displacements, and contact conditions; therefore it is important that you understand the behavior of your model.

In other instances

When trying to replicate experimental data or actual response in the field with simulation software. It is important to remember that the source of potential discrepancies is often in the setups. Therefore, it is recommended to carefully revise all the features prior to running the analysis. Those include boundary conditions, material properties, etc. . The more accurate the quantitative results you are seeking, the more careful you should be with the setup of your model and interpretation of results.

The good news is if you setup your model correctly you can be confident that the results are very close approximations of the physical or theoretical values.

Now, let’s dive into the resources available to you, depending on what product you are using.

Inventor Professional Stress Analysis

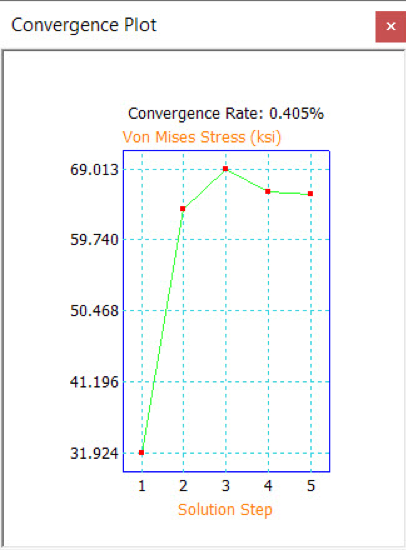

For Autodesk Inventor Professional, there is a built-in Convergence Plot option that helps users determine if their solutions has converged and what that convergence rate is.

Autodesk Inventor Nastran

In Autodesk Inventor Nastran, the software contains a Verification Manual built-in within the software.

The Verification Manual is a 264 pages long document with very robust examples that compare the FEA results to theoretical calculations and physical test results.

Inventor Nastran also has a Convergence Plot option to help validate the accuracy of the finite element mesh.

Autodesk CFD

For Autodesk CFD, there is a long list of verification examples that help validate results from the software. The verification examples are built-in directly in the online help of the software. You can also learn more here.

In the Autodesk CFD online help, there is also a Theoretical Background section for all stress simulation users. Those include fluid flow definitions, mathematical concepts, governing equations, and several other important resources.

Ansys

For Ansys Mechanical and CFD, there is a long list of verification examples that help validate results from the software. The following verification manuals are published to Ansys customers on the Ansys Help webpage. To obtain a copy of these verification manuals, please contact KETIV directly.

- Workbench Verification Manual

- Mechanical APDL Verification Manual

- Fluid Dynamics Verification Manual

In addition, Ansys works closely alongside universities and various industries in publishing white papers to research and verify the Ansys products.

I recommend taking a look at our white paper, Disruption in High-Tech is Here: How Ansys Software can help you Innovate.

————————————————————————-

About Nikhil Venkat:

As an Application Engineer, Nikhil has been engaged in consulting and education services for the last three years, with a focus on stress simulation, CAD and data management. He earned a Master’s degree in Mechanical Engineering from the University of Florida, and Advanced Simulation and Product Design certifications from Autodesk. He’s been working with KETIV, one of the manufacturing consulting firms in California that focuses on Autodesk Consulting and Ansys solutions.