Autodesk Moldflow for Plastic Injection Molding

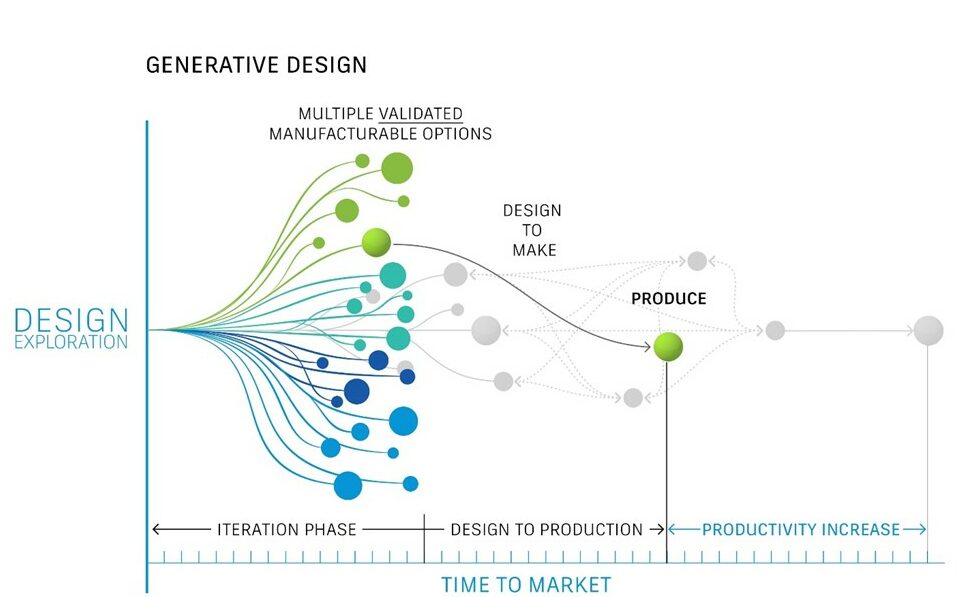

Assessing ideas and examining the effects of design decisions at an early stage of product development is crucial.

Use advanced simulation and modeling techniques to identify potential product issues before they become a problem. With Autodesk Moldflow, you can simulate every aspect of your manufacturing process, from the design of the product to the materials used and the manufacturing process itself.

Key Features of Autodesk Moldflow

Comprehensive Design and Analysis

Optimize your injection molding processes to improve efficiency, reduce waste, and increase productivity.

Moldflow Insight provides detailed analysis and simulation of the plastic injection molding process, including flow, packing, cooling, and warpage

Innovate Faster with Collaborative Design and Automation

Facilitate effective communication and collaboration between product design teams to minimize delays and reduce the costs associated with rework.

- Take advantage of the content collaboration features of Autodesk Drive and Shared View.

- Utilize the in-product Fusion 360 push feature to make rapid geometry changes.

- Leverage automation tools to streamline setup and post-processing.

Powerful Workflow Optimization

Moldflow Adviser offers quick and easy analysis of the injection molding process by utilizing pre-defined settings and templates, making it ideal for beginners or those looking for a more streamlined approach.

IDEX Health & Science

Optimize your plastic injection molding process.

KETIV Partners with Bozilla

Injection Molding Optimization and Consulting Experts

Bozilla Corporation has 20+ years of Plastics Industry experience to assist with injection molded part development, using the latest Autodesk Moldflow software and geometry techniques for high-quality results.

Providing Advanced Simulation Analyses

- Flow analysis

- BEM Cool, FEM Cool analyses

- Warp analysis, Reverse Warp (Windage) analysis

- Gas Assist analysis

- Co-injection analysis

- Autodesk Moldflow MPI/3D, MPI/Fusion Dual-Domain and Midplane technology

Autodesk Moldflow Training

Bozilla Corporation is an authorized Autodesk training center, with 14 years providing Autodesk Moldflow software training to plastics professionals in the injection molding industry.