Tired of redoing your work every time you tweak a CAD model in the middle of a simulation?

You’re not alone. This guide walks you through how to set up true live parameter sync and bi-directional tracking between Autodesk Inventor and Ansys, eliminating repetitive work and boosting your simulation productivity.

Why Use Live Parameter Sync?

If you design in CAD (Inventor) and analyze in FEA (Ansys), you know the pain of having to update both models separately. Live parameter syncing makes parameters instantly available on both sides, so any change in geometry or variables flows automatically back and forth. No more importing neutral CAD files or manual updates, just true bi-directionality.

Step-by-Step: Syncing Parameters Between Inventor and Ansys

1. Create and Parameterize Your Model in Autodesk Inventor

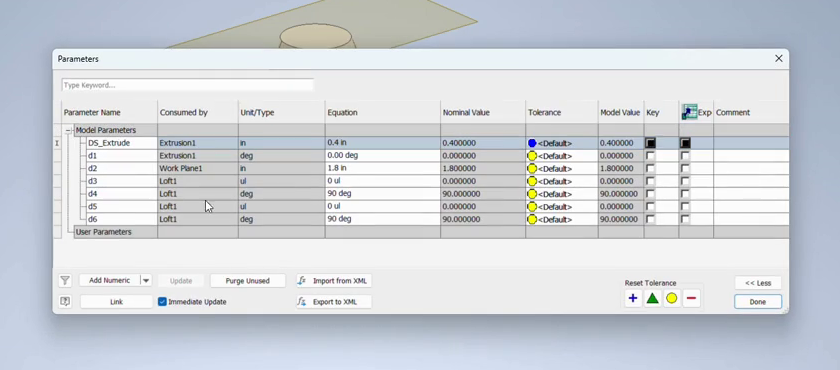

Open Autodesk Inventor and create your part or assembly. Assign geometry parameters (like height, thickness, or angle) to features you want to control.

2. Rename Inventor Parameters with the “ds_” Prefix

In Inventor, go to the “Manage” tab. Locate your key parameters and rename each by adding the prefix ds_ (for example, ds_height, ds_angle). This prefix makes the parameter recognizable to Ansys.

3. Save the Model and Launch the Ansys Plugin in Inventor

Save your Inventor model. Use the built-in Ansys plugin for Inventor to prepare for export. The plugin establishes a live link to Ansys Workbench or Discovery.

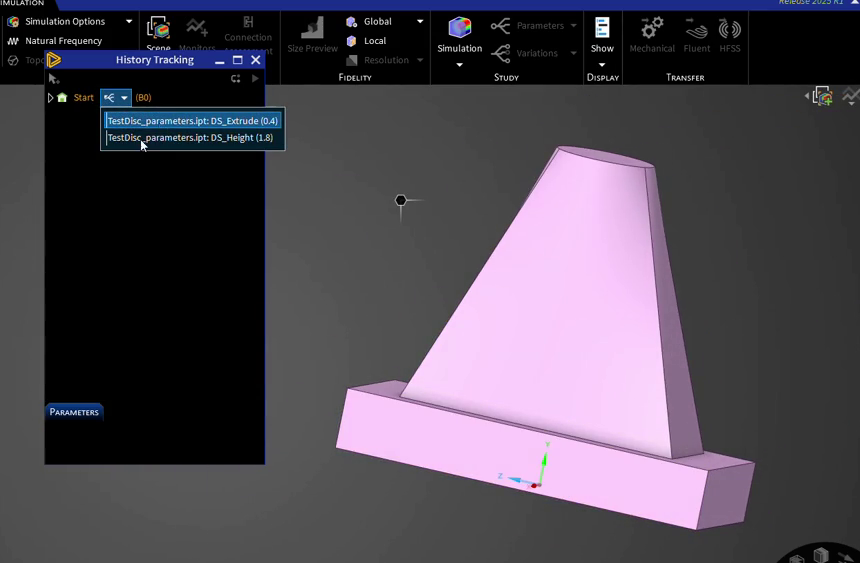

4. Transfer Model to Ansys Workbench or Discovery

Use the plugin to open the model in Ansys Workbench or Discovery. Your parameters (with the ds_ prefix) will now appear in the Ansys parameter manager. You’ll see a “history tracking” window, indicating the connection is live.

5. Modify Parameters in Either Environment for Bi-Directional Sync

Adjust a parameter (such as height or sweep angle) in Ansys Discovery’s parameter set and see the update reflected automatically in Inventor. Make changes in Inventor, and those are tracked and updated in Ansys as well. This live tracking works for simple parts or more complex geometries, like turbines.

6. Reuse Parameters in Downstream Simulation and Analysis

Parameter sets created and synced this way can be used directly in Ansys Workbench for structural, thermal, or other analyses. No need to recreate geometry or parameters, everything stays synchronized and ready for optimization studies.

Conclusion

Integrating live, bi-directional parameter sync between Autodesk Inventor and Ansys transforms your design and simulation workflow. With this powerful feature, you can quickly iterate, optimize, and validate models without the hassle of manual updates or duplicate work. This seamless connection helps teams focus on engineering innovation rather than tedious file management. If you haven’t tried live parameter sync, it’s time to boost your efficiency and accuracy, streamlining every project from concept to final analysis.