How do I get an Inventor model into Revit? How can I easily transfer models from Inventor to Revit? Am I able to open up an Inventor model in Revit and save it as an RFA file? Can I export an Inventor model to an RFA file? Can I save as my Inventor model to an RFA file? I receive these types of questions from customers on a weekly basis and there is a solution. It’s called the “BIM Exchange Environment” within Autodesk Inventor 2016.

Inventor to Revit: Significant Business Benefits

In Inventor, you can “save as” or “export” a model to multiple file formats including ADSK, DWG, SAT, STEP, etc., but not to an RFA file. An RFA or (Revit family file) is a feature based parametric file that can be directly loaded into a Revit project.

Currently, Revit is the industry standard tool for AEC (Architecture, Engineering & Construction) and BIM (Building Information Modeling). As a matter of fact, a majority of product manufacturing companies are being pressured into making their products readily available in an RFA file format. By providing BIM compliant models and data, their products are more likely to become specified by architects and engineers during construction planning. This BIM data is accessible throughout the entire lifecycle of a project. Therefore, it preserves a longer aftermarket relationship with their customers. It also strengthens their relationships with different parties. Those include architects, engineers, contractors, and facility owners.

Unique Competitive Advantage

Other 3D software packages offer tools to simplify model geometry with the ability to export, but only to a neutral file format with limited component metadata. However, what they don’t offer is the ability to provide connection points when exporting. What’s more, they don’t have the capabilities to transfer physical and visual characteristics of the model over to Revit.

With Autodesk Inventor, the BIM Exchange tools provide a purpose-built workflow that allows users to simplify their models and creates a custom user coordinate system. What’s more, here is what others Inventor can do:

- Define important connection points

- Input BIM parameters

- Export the model to a native Revit format with all physical and visual aspects intact.

By providing an intelligent lightweight version of a model to architects and engineers with all the aforementioned features, product manufacturers are able to win more jobs by utilizing their products in Revit projects. As a result, this makes it easier to transfer models from Inventor to Revit.

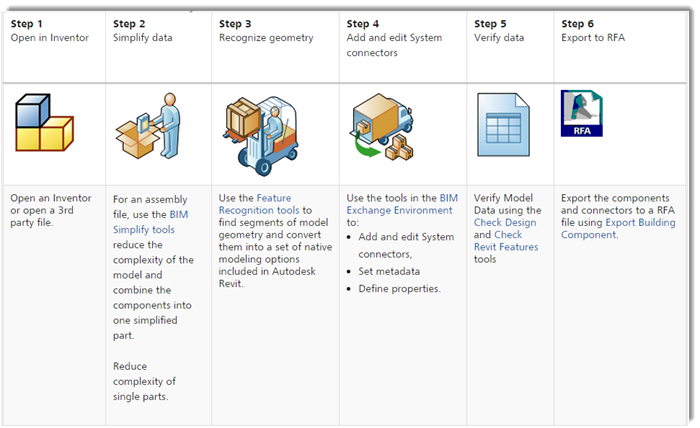

Inventor to Revit Family File (RFA) Workflow

The workflow shows you how to create a simplified product and publish a native RFA file. Click here for more details.

In Conclusion

The adoption of BIM is rapidly increasing in North America and globally. It is extending throughout all phases of building design and construction. If Revit families have not yet been requested in your companies sector of the industry, they soon will be. Nowadays, construction companies are finding extreme value in products with BIM data and simplified levels of geometry that can be easily read in their BIM applications.

Neutral file formats do not provide the necessary information they are looking for. The direct connection between Autodesk Inventor and Revit provides a dedicated process of integration. It integrates an Inventor part or assembly directly into Revit with BIM compliant information. Those include cost, size, vendor, and system requirements. It creates better collaboration, better cost predictability, less errors, and ultimately reduced construction costs.

Join the Autodesk Virtual Academy community and never stop learning.

Are you wasting your time managing data? Click here to see how to effectively manage them.

Hello

We are trying to convert a fully functional 2018 inventor assembly into a parametric Revit family. Is this possible? Everything works in inventor but all parametric smarts are lost in Revit. We end up with a dumb object. There is no advice that this can’t be done.

Thanks in advance.

Morgan

Hello,

I am looking for the response to this exact question. I do not see a previous response. Is it possible to export full parametric models from Inventor into Revit?

Thanks,

Cristian T.

Hi Cristian,

Thanks for your question. Parametric models from Autodesk Inventor can be exported as Revit Families following the BIM Content export process. You will want to simplify the model first using Shrinkwrap to create a fully detailed model for a BIM representation. In the BIM Content environment, you will need to add BIM connectors and add any metadata for your product using the Revit Omniclass list. Then export your model with either of the compatible BIM file types (.rfa) (.ifc) or (.adsk). Hope this will answer your question.

Thanks,

thank you very much admin for your important news to share with us. And more thanks for i get best idea read this article about this topics. many more days i was searched this topics, finally i got it.

Thank you for your comment!

Glad you enjoyed this blog! Make sure to subscribe to our blog at https://ketiv.com/blog/subscribe