From ubiquitous everyday consumer products to medical devices and high-performance precision parts used in space exploration, the impact of plastics in design and manufacturing is undeniably wide-ranging. For over 100 years, plastics have been used in such a wide range of applications because they are uniquely capable of offering many different properties that offer consumer benefits unsurpassed by other materials. They are also unique in the process used to produce them – injection molding.

For every injection molded plastic part created, there are a potentially limitless number of ways to design and manufacture it. Every mold engineer wants to find the way that produces the best results, whether functional or cosmetic or both, for the lowest cost. However, this can be incredibly difficult to do, whether you are designing a simple housing or a complex manifold.

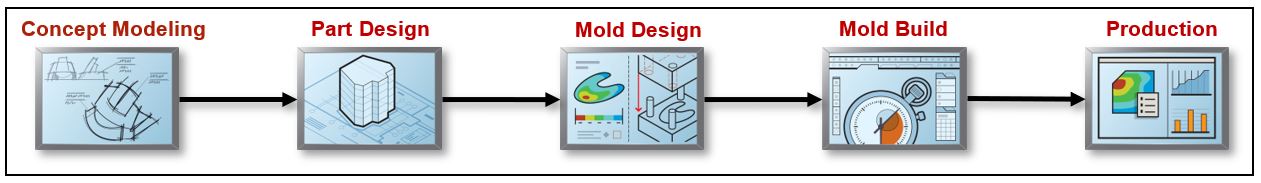

Fig 1(a): Injection molding process

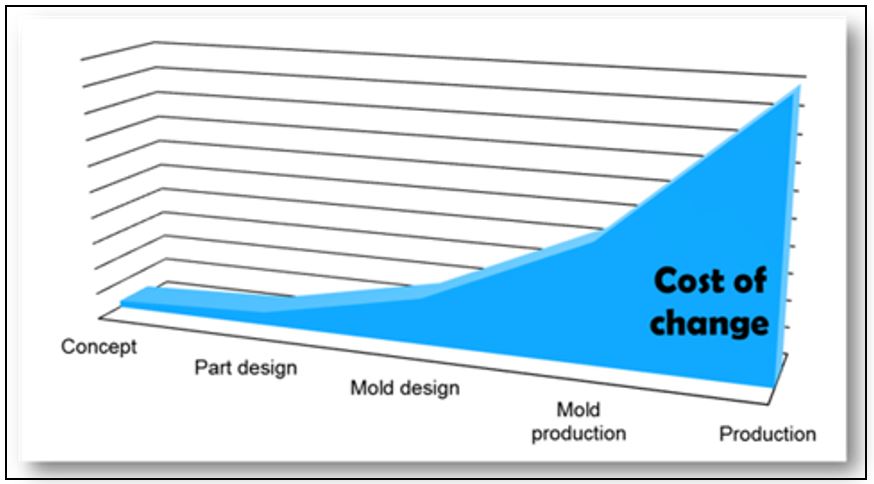

Fig 1(b): Cost of making changes increases exponentially as the process progresses

Injection molding can improve efficiency and boost profitability

Injection molding is not just a complex process. It is likely the most complex of all widely used, high-volume manufacturing processes. Within each of the four major factors in every project (part design, material, process, and mold design), there may be a dozen or more variables that can dramatically affect the outcome. Many of these variables are directly connected to others, both in ways that are obvious and those that are not.

Most engineers rely on expertise and experience to make critical choices about the part design, process, mold design, and part material they are creating and if they’ve designed a similar part many times, using the same trusted process, why change it? And because all of this happens very early in a project’s timeline, this effectively limits what can be optimized as a project evolves, with the cost of change being a major barrier to change [Fig 1(b)].

Most of the time, this is a smart way to go. But there are specific cases when “opening up” the design phase to more exploration reveals opportunities to reduce cycle time, improve efficiency, or boost profitability in ways that you had not considered or assumed were unavailable.

Exploration

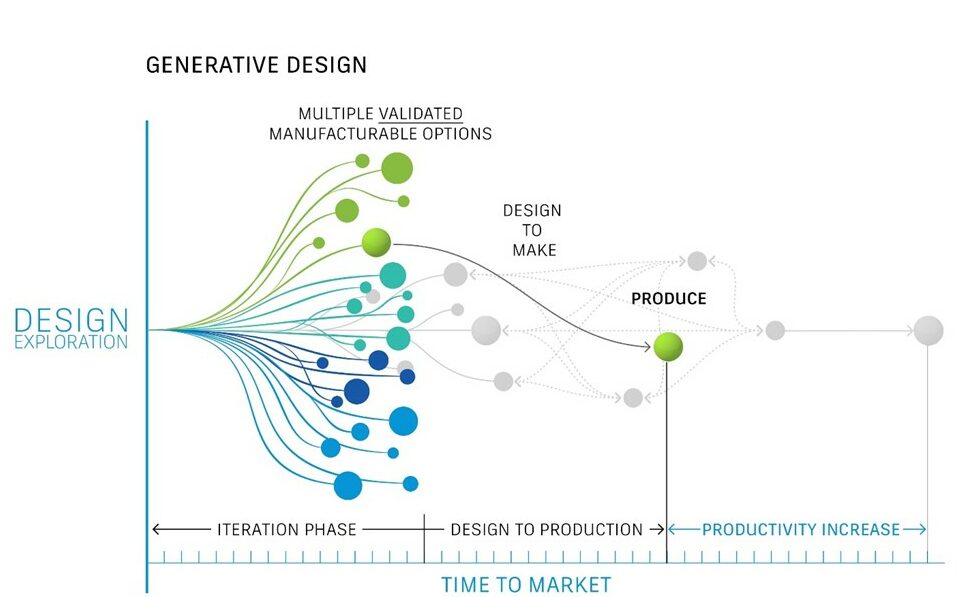

Exploration deals with big, early decisions. Are you going to use traditional injection molding, gas-assist, or micro-cellular techniques? Are you going to use traditional cooling, conformal cooling, or high conductivity inserts? Are you going to try a new material? This last example is the essence of exploration: the choice between sticking with a trusted approach or trying a new one. Obviously, using a proven method carries fewer risks. But new ideas can deliver huge payoffs, especially if you can explore them within an acceptable time frame and with enough precision to proceed with confidence.

The kind of exploration that mold engineers can use on relatively short timelines is driven by simulation software. Simulation tools can be used to test different “big decisions” quickly. The idea is to build confidence into your idea, so that you can predict what will happen and be reasonably certain it is a viable alternative to the default process.

The design of the part and the selection of a molding process go hand in hand. If you use gas-assisted injection molding, then the part must be designed so the gas can help hollow it out. If you prefer micro-cellular foam injection, the walls must be thick enough to withstand the process but not so thick that they create shrinkage issues. These kinds of adjustments must be made concurrently, so it is useful to consider both when it comes to upfront exploration.

Fig 2: Generative Design in Autodesk Fusion 360 leverages artificial intelligence to output dozens of design options

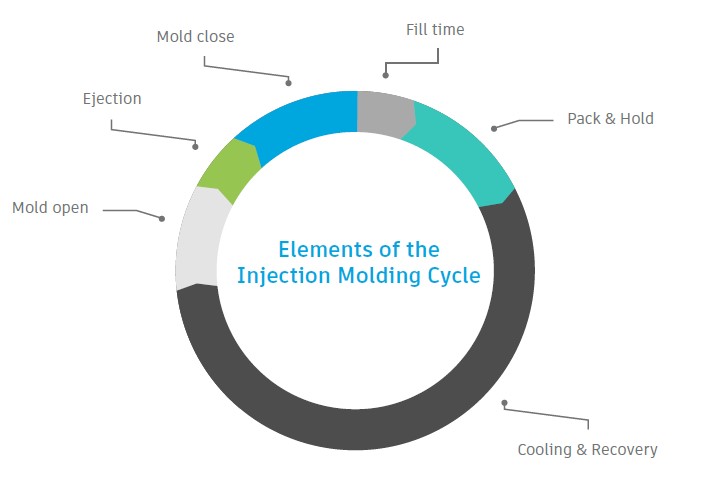

Even small changes in cooling time can have a major impact on cycle time, so exploring various cooling systems can produce useful results. And it can be done relatively quickly. When exploring cooling systems, the point is not to design cooling channels around ejector pins or other components of the mold, but to perform a high-level comparison.

Fig 3: Cooling is a major factor in determining mold design

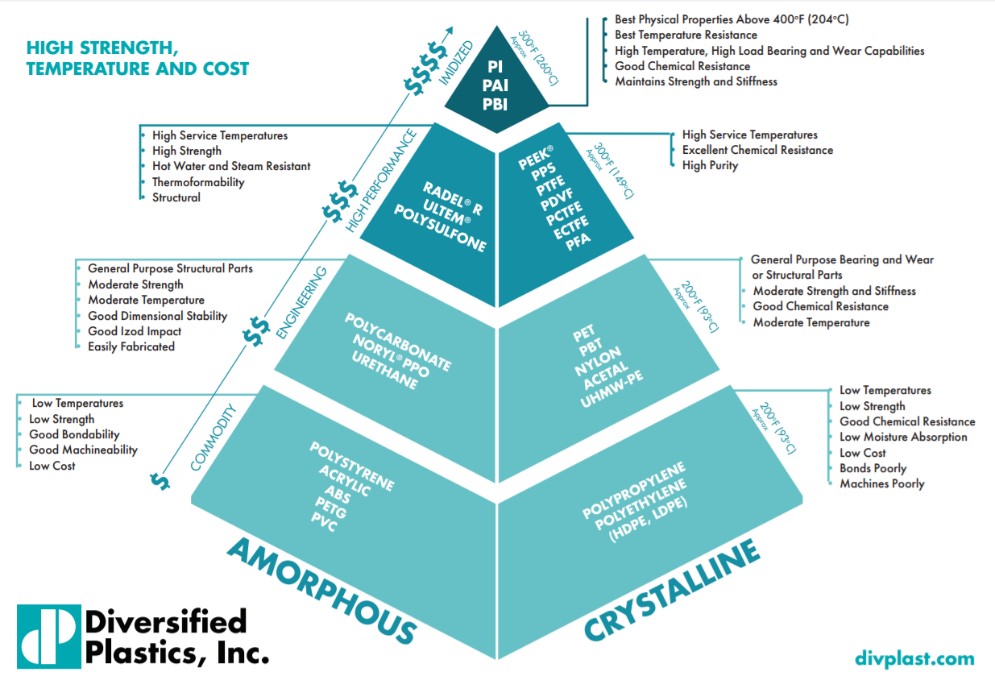

Fig 4: Upfront exploration also helps with selection of material

As with the mold design, the goal of material exploration is to narrow the field to one family that has better molding characteristics for the part being manufactured. Later, you can use this insight to save time during the design and optimization stage. Because material comparisons are comparatively simple, they can also be done concurrently with part and process design or mold design.

Optimization

In general, there are many ways to optimize the variables of injection molding, most of which involve simulation software such as Autodesk Moldflow. The realization of our unique & differentiated vision of process design and manufacturing typically requires several elements:

- a rich repository of process-aware material data to power accurate insights

- a design optimization solution like in Autodesk Moldflow Insight, capable of leveraging the accumulated knowledge, expertise, and imagination of the engineering team

- comprehensive process analysis to capture the impact and possibilities of manufacturing

- a rich toolset of post processing treatments and hybrid applications to reflect the final as-designed intent

- a suite of analysis solutions capable of capturing the combination of materials and manufacturing process so the physical response of the as-manufactured design can be properly understood

- a combined model reflecting the reality of materials and manufacturing process interactions so that a physical response of the as-manufactured design can be properly understood

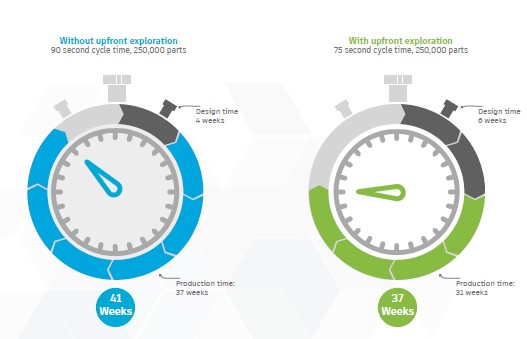

Fig 5: Design and production cycle time comparison with and without upfront exploration

Upfront exploration and optimization help you understand which approach will work best for a given project, or which aspect of a project would benefit from further exploration. This expertise gives mold engineers a distinct advantage for overcoming new part design challenges, process requirements, and material characteristics, as well as dealing with the familiar pressures of time, cost, and profitability.

If you are interested in learning more about plastics and injection molding, take a look at our 4-part webinar series, Plastics 101.

Highly commendable work! AutoCAD has turned many corners to reach where it is today. Top of the list! Have known about it since long.

Thank you Manohar. Glad you enjoyed this blog! Make sure to subscribe to our blog at https://ketiv.com/blog/subscribe