I’m in the middle of a machine design that the client wants to be all mechanical. Well, they are allowing a couple of limit switches, but other than that, it’s completely mechanical. Three of us here at KETIV are each putting in effort to get this assembly finalized. I am working on the internal mechanism so, of course, I am going to use Autodesk Inventor. Not soon after I got into some details, I realized there were some timing constraints on this assembly that are trivial to solve when a microcontroller is available, but are less obvious when it’s completely mechanical. In one revolution of a shaft, I had to have another shaft stop, start, stop, and then start again.

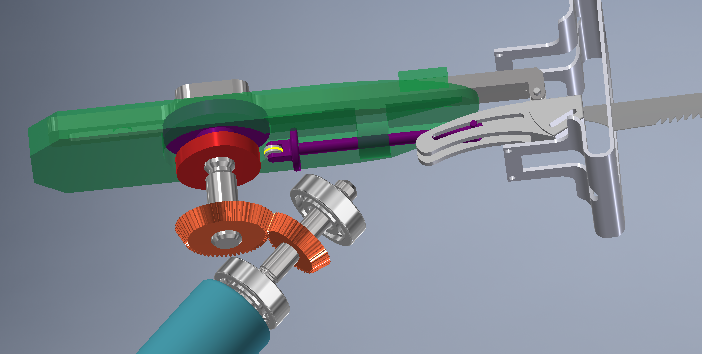

Uh oh. How do you do that? I thought about Geneva Mechanisms and Intermittent gearing. I was sketching on paper for quite a while and then got to the point when it was time to do some solid modeling. The Inventor tool itself was useful to define the contact between the driving “gear” and the driven “gear.” It did not, however, offer the kinematic and dynamic information I was seeking.

It was actually a client of ours that reminded me about Dynamic Simulation. I hadn’t used it in years, but working with it is a lot like riding a bike: You do it once, and you never forget.

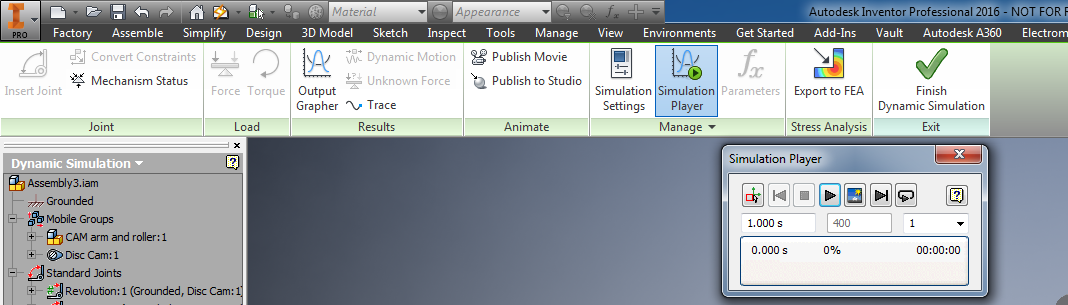

I brought my intermittent motion assembly into the Dynamic Simulation Tool, which you can find on the Environment tab in Inventor 2016 Professional.

A dialog box appeared and I took them up on their offer to view the Dynamic Simulation Tutorial. Autodesk provides a nice reciprocating saw model you can use to brush up on your Dynamic Simulation skills.

With that, I had my intermittent drive train running and saw that if I did not have at least some shaft damping, those two wheels were going to eat each other apart. As it turns out, we are required to have shaft seals, so they can serve to provide the required damping.

With the kinematics and rigid body dynamics out of the way, I was clear to continue. I am back to just plain Inventor. You can bet after the next non-trivial subassembly is modeled, I’ll be back to Dynamic Simulation for insight.

Register for upcoming Autodesk Virtual Academy session.

Great article Chris!