What are the skills for the future of Autodesk generative design?

When I started out as a mechanical designer at Hollywood Film Company, the first thing my manager did was put me to work on the company’s assembly line. I thought to myself, “This isn’t what I signed up for,” but he explained that to make improvements to their product.

As an industrial film splicer, I first needed to understand how it was assembled from the ground up and used in the field. I’ve always loved putting things together, so I jumped right in. This early experience was key to my growth at HFC; developing this brain muscle helped me improve their products and eventually design new ones.

Learn the fundamentals

I continue to think it’s important to first learn the fundamentals whenever we as designers have to tackle something new. And – for better or worse – during this period of rapid technological evolution in manufacturing, that’s fairly often.

Take Autodesk generative design, for example, a technological development that will radically change the role designers play in product development. In Autodesk generative design, the designer doesn’t come up with the design solution in the way they do today. Instead, they define the design goals and requirements. Then, they let the computer come up with design solutions that meet the requirements. These shapes often end up being things no designer would imagine. Designs that only use the amount of material necessary to maximize performance while wasting nothing.

Autodesk Generative design is here today! Manufactures have been using in real applications. Soon it will be a common design approach that affects all of us. When that happens, product designers will go from people who devise creative solutions to people who define creative requirements and objectives, a fundamentally different way of thinking.

So How Can We Get Prepared & Not Get Left Behind?

How to use simulation tools to test designs

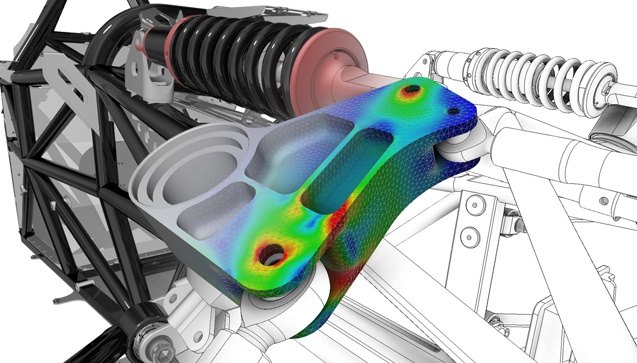

The first is to regularly use simulation software within your CAD platform to test your current designs. You define the factors that you want to test, then run the test and analyze the results to see how your design will perform under real-life conditions. For example, if you’re building a structural frame, you can test the model by simulating weight, vibration, and any other stress your design will face in the field.

Not only does this tell you whether your design is strong enough, it will also tell you where you can potentially remove material to lighten the product and save material. But most importantly, going through the simulation process will improve your ability to define problems accurately and review results.

You’re flexing the brain muscle and building the skills you’ll need to succeed at generative design. Engineers who’ve used these Simulation tools are very comfortable with generative design and have the right foundation to excel at generative design in the future.

How to create product configurations

The second way is for engineers to create product configurations using tables and equations in your CAD platform. This allows you to build the product options and specifications you use to configure your product in Excel or another business system into your CAD model. For example, if I manufacture lighting ballasts that come in different lengths, widths, Lumens, and colors, I can build one light ballast CAD model and incorporate all of these rules and permutations into my design.

When I need to build a second, I simply change the options I’ve exposed and a new configuration appears. Doing this allows you to gain practice defining problems and setting up equations until you ultimately get the model to perform the way you expect. This skill is critical with generative design. Your design will only be as good as your specification.

In conclusion

The rapid changes shaping our industry will provide new opportunities, but only if we can adapt. We need to break away from the limitations, rules, and design restrictions we have followed in the past. We must continually question old habits, build new skills, and think in new ways. The two suggestions I’ve given for skills development will help you improve your product designs, but more importantly, they will help you prepare to become the designer of the future.

Here are some tutorials that will help you start using these features:

Simulation videos

iLogic videos

Limitations in software, materials and manufacturing are a thing of the past. Embrace the change by starting to use the tools you own today.

One way you can stay ahead of the curve and commit your team to adapt is through Autodesk Virtual Academy – an ongoing series of free weekly training webinars from KETIV.

I’d also like to connect with you to learn how these features are affecting your workflows. Call me at 714.458.3386 or email me at anthony.rodriguez@ketiv.com.