There is a massive market wave

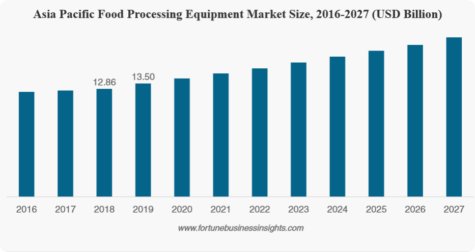

The global food processing equipment market is witnessing an unprecedented era of growth, expected to soar from $45.01 billion in 2019 to a staggering $62.98 billion by 2027. This expansion is not without its challenges. Your industry grapples with a critical shortage of skilled labor, a factor directly impacting the efficiency of production lines and overall market growth. The demand for processed and packaged food is driving a significant shift towards automation and advanced technology, propelling the market to an anticipated $69.3 billion by 2032.

Competing effectively means evolving

Manufacturers are at a crossroads, where adapting to rapid technological advancements, stringent food safety or other regulatory compliance, and evolving consumer preferences are paramount. The industry faces intense cost pressures, making the balance between cost-effective manufacturing, quality maintenance, and innovation more crucial than ever. In this dynamic landscape, strategic adaptability, technological integration, and a keen understanding of industry trends are key to not just surviving but thriving in the future of food processing machinery.

Case Study: TOMRA Fresh Food | Compac wins more with frictionless ordering

“We have a unique competitive in our specific marketplace with this solution….we’re the only ones in this space, doing it this way.”

Better customer experience

Customers can finally see how their sorting system connects to the rest of their factory and operations. TOMRA Fresh Food | Compac has an inherent competitive advantage now, as customers have a better understanding that they are buying a complete sorting solution, not just buying machines and parts.

Faster and easier selling

The TOMRA Fresh Food | Compac team can now quickly create 3D models that they can send to customers, accelerating the sales cycle. Their Solution Engineers can create 3D renderings in real-time, as they pitch the solution.

Reduced time and waste in projects

The Solution Engineers use Autodesk AutoCAD and Autodesk Inventor to quickly and efficiently create a sorting system from a library of components, rather than from scratch. The company’s order configuration data is more accurate now, reducing rework and errors on the shop floor.

You build the equipment that feeds the world.

The food manufacturing consultants at KETIV can assist in your goals to get food to the people, make it easier on your teams, and sustain better futures for those on the planet. Together, we can make a bigger impact, sooner.