Last Wednesday, October 19th, KETIV and Autodesk hosted a What’s NEXT in Manufacturing Forum at the Bowers Museum in Santa Ana, CA.

Among the presenters, Autodesk Sr. Vice President of Products, Amar Hanspal, revealed trends in the manufacturing industry and methods to stay competitive.

Let’s dive into what we learned and what Autodesk has in store for the future.

KETIV President Kanwar Anand kicked things off with a quick overview of the day’s agenda and shared his perspective on the ever-changing world of product design and manufacturing.

The Future of Manufacturing

Next up, Amar gave an urgent presentation on how the means of production are changing, prefaced with a comparison between the software industry of the 1980’s and today. In the 1980’s, there were a few dozen software companies. Everybody knew each other and the playing field was small. Today, there are hundreds of thousands of software companies. The act of producing software has changed in a similar fashion to changes we’re now seeing in the manufacturing industry. This puts manufacturers in an advantageous seat with the ability to look back, apply lessons learned, and invest in products such as Industry Collections and cloud-based products for the future.

What’s NEXT in Manufacturing?

Additive and subtractive manufacturing have also impacted the industry. 3D-printing is no longer just for prototyping as it was in the past. It’s now being used in high value, low volume production, which speeds up production time and reduces overhead cost. This can be seen in the medical device industry with surgical instruments, dental restorations, and even customized designs for prosthetics.

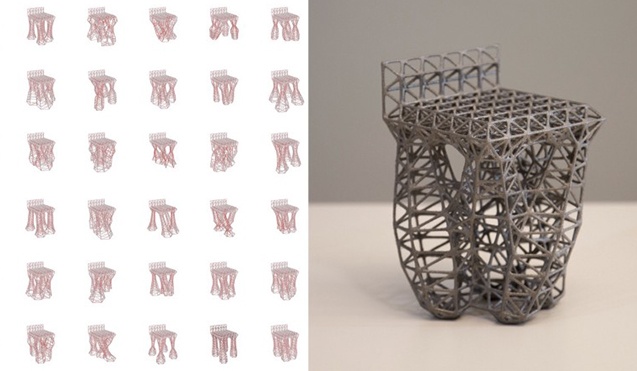

Amar went on to discuss Generative Design and its ability to allow the designer to input what he or she wants, such as constraints or limitations, and the tech will produce thousands of different shapes and options. Until now, if you couldn’t draw it, you couldn’t fully imagine it. This new breakthrough is all about telling the computer what you want to accomplish. Generative Design is important because it’s an entirely new way of doing things and the benefits are staggering – lower costs, decreased time to market, efficient material consumption, etc.

Look at a product as simple as a chair. Instead of drawing a chair and spending hours changing the look and shape, you can tell the computer you want to build the chair within weight, support, and cost constraints. The software will provide thousands of options and give you the ability to choose the design that meets the most important criteria.

With a decrease in cost and an increase in computing power, Generative Design has started to make its mark across the entire industry. Computers now calculate complex shapes to figure out the most optimal configuration. This can push the bounds as to what constitutes a parameter, and allows us to optimize designs without over-engineering.

As the nature of products is changing, the need for smart products increases. The invention of the smart phone indirectly affected the rest of the manufacturing industry as the price of it’s components decreased drastically. With significant decrease in size and cost, information feedback loops and preventative maintenance are possible.

[Check out Amar on Episode 33 of Technotopia discussing the future of manufacturing and tools like Dreamcatcher that push manufacturers towards the adoption of Generative Design.]

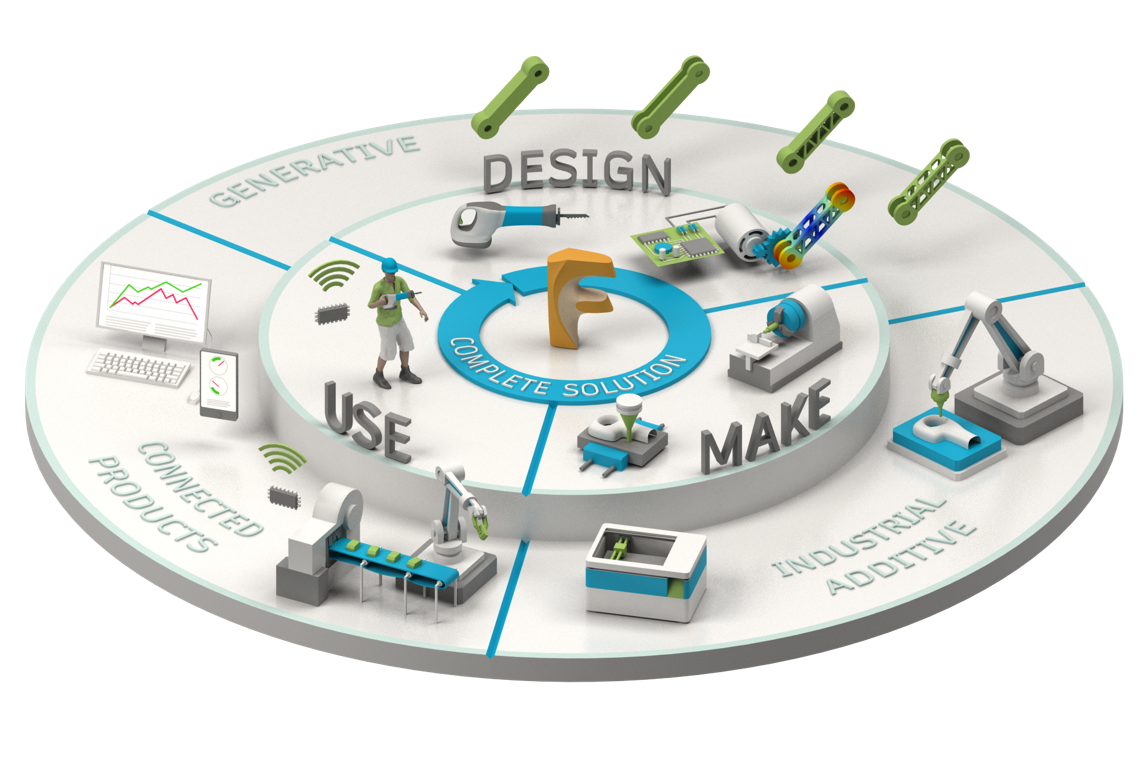

What has Autodesk done to help with this transition? The answer is its cloud-connected product innovation platform. This brings together a set of connected tools for design, manufacturing, and IoT in a single data-centered platform. Autodesk’s cloud-based platform, Fusion, acts as the foundation by supporting new ways products are designed, made, and used while providing access to tools for the top manufacturing trends.

Gone are the days of the need to work with a dozen different software products. With Autodesk’s product innovation platform, and Fusion as the backbone, you can use one single platform and its pieces as needed. The platform offers simulation tools, CAM tools, Fusion Lifecycle, and connected capabilities.

Fusion Lifecycle

Next up was Ross Millenacker, Product Manager for PLM at Autodesk. Ross introduced Fusion Lifecycle, Autodesk’s new tool to help your team through the entire design and manufacturing process. Watch this quick video for a quick rundown of his presentation:

Ross discussed the idea that the cloud has revolutionized IT, consumer, and enterprise applications. There are many advantages to this – lower cost of entry, ease of use, higher performance, and instant access to new features. Product innovation software, such as CAD, PLM and PDM, has lagged other enterprise applications such as CRM. Traditional PLM vendors lacked the incentive to invest in ways to improve the technology. Autodesk recognized this and decided to develop the necessary tech and infrastructure to move its offer-set to the cloud.

The benefits continue for customers using Fusion Lifecycle. Manufacturers are now witnessing new areas to engage the end-user, increasing interest and excitement and providing a positive impact on company innovation. This also brings solutions to long-standing technical issues. One of the most impactful areas discussed was in Predictive Maintenance, the ability for sensor technology and cloud-based analytics to provide businesses with granular visibility into the critical systems running their facilities.

Fusion Lifecycle removes the need for manual processes and multiple, disparate systems. The result is an increase to collaboration, customization, and customer experience.

Conclusion

As I walked past the historical artifacts of the museum, the importance of what I’d just seen became seemingly more clear. The world is moving at break-neck speed. We need to utilize these new tools to keep up or soon – very soon – we will be history much like the items hung on the walls of that museum.

For more info on how KETIV can help you build better products into the future, join the Autodesk Virtual Academy community. Never stop learning with our weekly, free training webcasts.