Fusion 360- Manufacturing Made Easy. Manufacturing has always been interesting to me. The fact that you can design a part within CAD software and then physically watch it get built is something that will forever intrigue me and motivate me to design. Growing up, I loved taking things apart, seeing what was inside, and learning how it functioned. Granted, I wasn’t always able to put things back together. But I was learning. And that was exciting to me.

Some years passed and I decided to pursue a career in Mechanical Engineering. I’m currently a 5th year Engineering student at California State University, Fullerton with an emphasis in Manufacturing.

Engineering seniors are required to work on a senior design project. I decided to join the SAE Baja Team and make that my project. Off-roading has always been a passion of mine and I was really thrilled to work on a school project with something I’m passionate about. The first semester was focused on design and calculations. All of this (and I do mean all) was done on SolidWorks. This was the only software installed on many of the school’s computers.

Towards the end of the semester, I was hired at KETIV. My role here is to provide support for anything Fusion 360 related. I wasn’t a Fusion 360 expert by any means when hired by KETIV. In fact, the only other Autodesk software I had used was AutoCAD. This led to some nervousness about learning every detail to Fusion 360. Surprisingly, it didn’t take long to get comfortable with the software.

Fusion 360 makes it extremely simple to transition over from other software. It lets you customize certain keys and mouse gestures to operate like some of the other programs you may be used to.

Since Fusion 360 is a CAD and CAM tool, I saw an opportunity to program the machining for my senior project and machine our parts in-house. Not only did we save time by not relying on a machine shop, but we saved money by not outsourcing the work. Since our project designs were made in SolidWorks, we had to transfer parts into Fusion 360. Fusion 360 was able to convert and transfer those files without any problems.

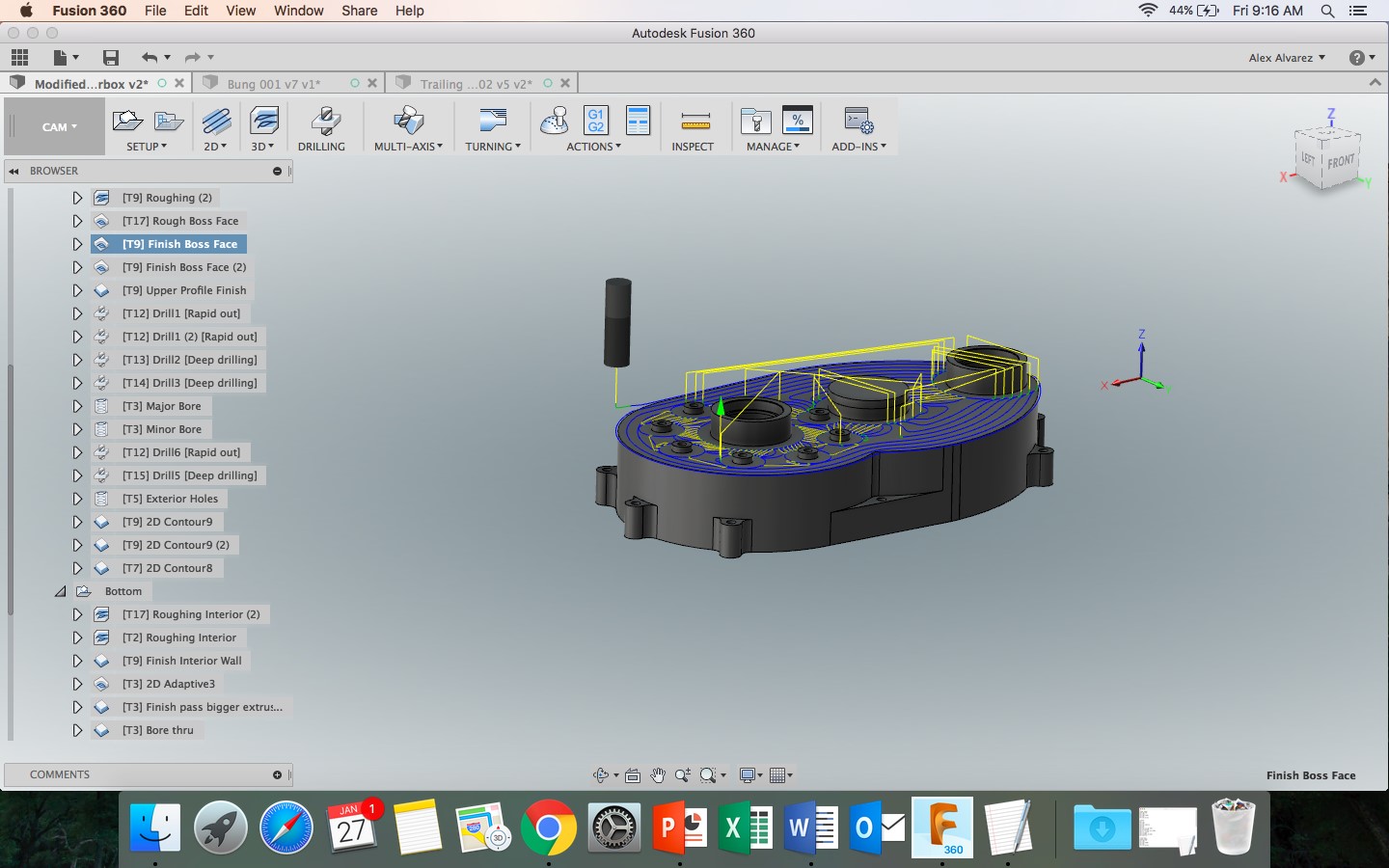

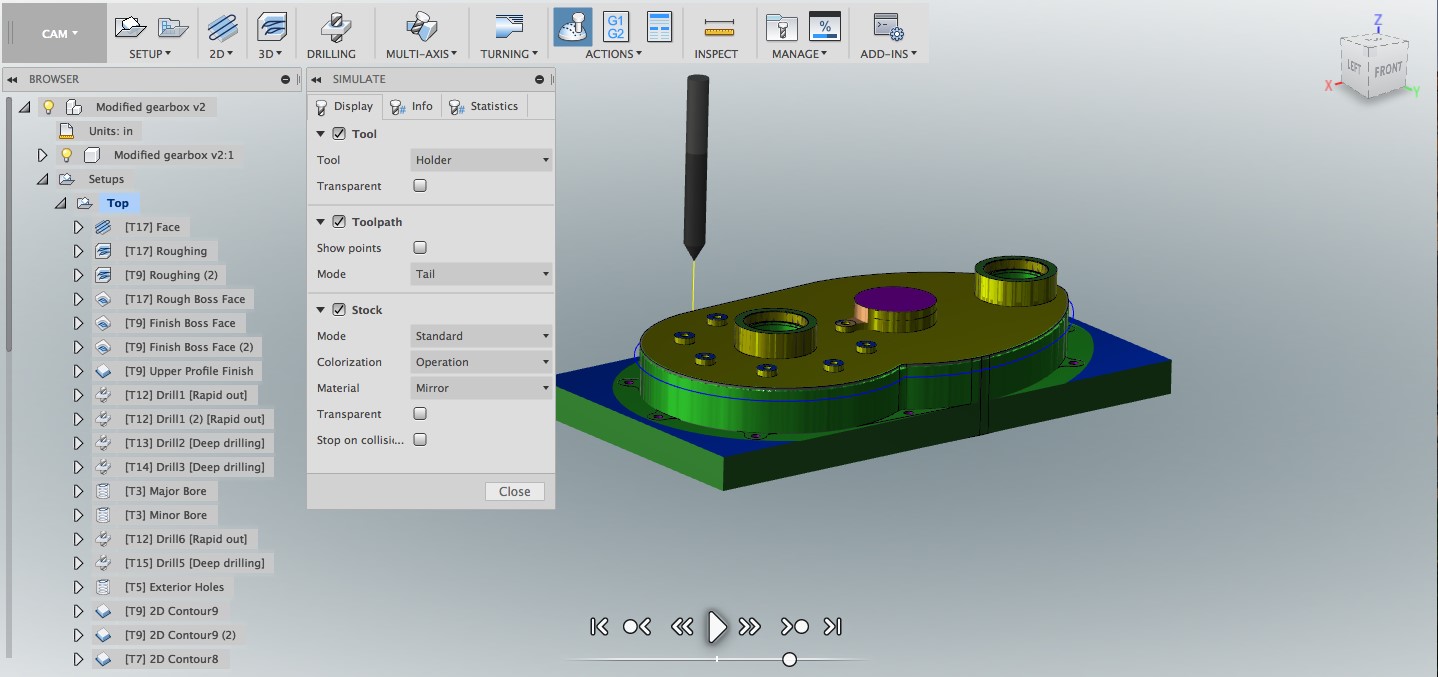

Below are some parts we are currently working on and are in the process of machining. Here’s the custom gearbox we designed. Fusion 360 comes with simulation capabilities that allow you to visualize exactly what the machine will be doing. This way, you can be confident there won’t be any surprise collisions or movements.

1/2″ End Mill with a finishing pass on top

Spot Drill making a small hole for #7 Drill Bit which will then get tapped

Here, I’m verifying the machine is going the correct depth. Since our machine doesn’t have the tool length probe, we had to set it manually. Any error could result in the machine crashing down on the part.

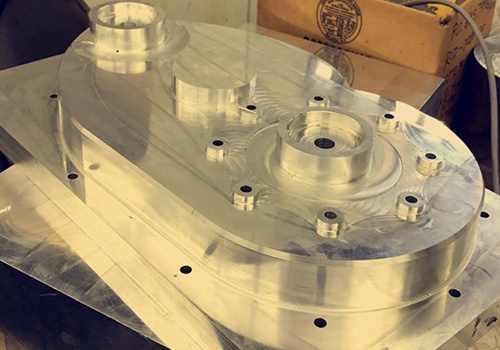

Here is the finished top cover. Our next step is to bolt it down to the fixture, create the outside profile, and shell it out.

In addition to the gearbox, we also needed to get the rear hubs machined. The hub connects the axle to the wheel and supports the wheel and tire.

Here’s another neat thing about Fusion 360. It has a tool integrated into the software called Proto Labs. This allows you to get a quote within 24 hours without having to pick up the phone and call a machine shop.

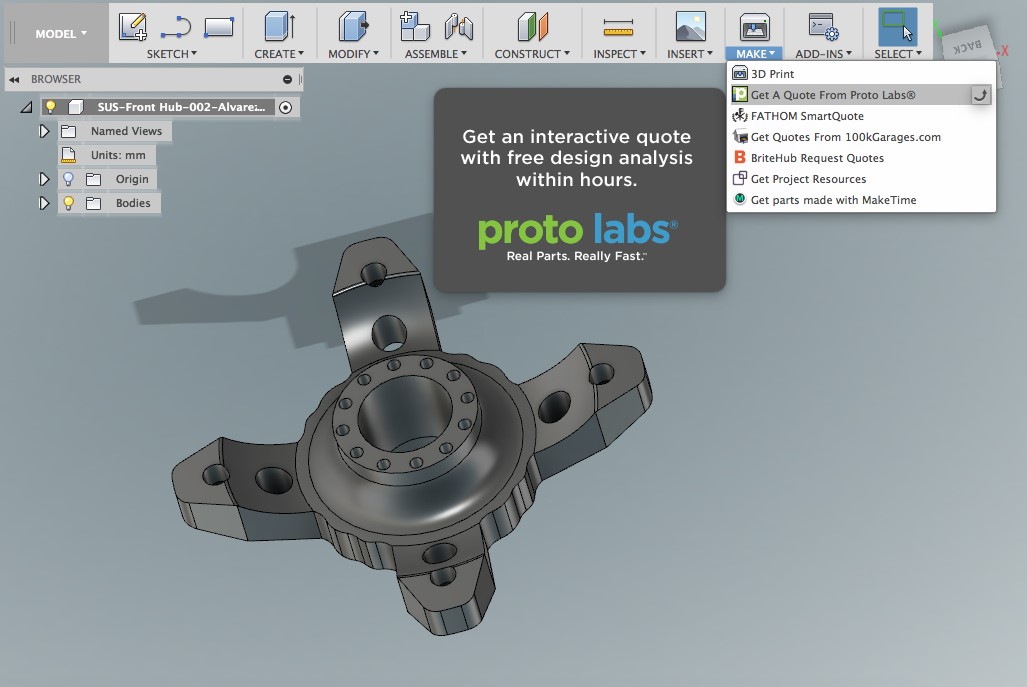

The process is simple. While working in the model space inside of Fusion 360, click on the ‘Make’ icon and select ‘Get a Quote From Proto Labs.’

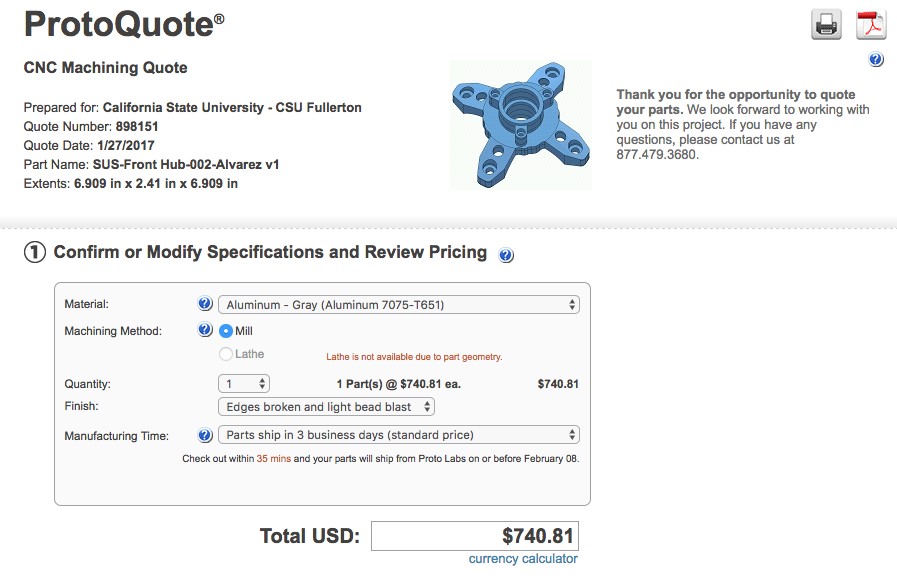

Simply follow the onscreen instructions and you’re done! Within a few short hours of sending in my part, one of their representatives emailed me with the feasibility of machining the part, how long it would take, and the cost. Here’s the breakdown:

Being that we are trying to be conservative with our budget, we decided to keep the critical dimensions and have a more simple design. This lets us do the machining internally and save over 50% of what we would have spent outsourcing.

While Fusion 360 is a fairly new software, it is making a great impact on the design and manufacturing community. Feel free to give it a try and let me know what you think. You can reach out to me in the comments below or email me directly about any of your projects at Alex.Alvarez@ketiv.com.

Join Fusion Fridays – free training webinars providing tips and tricks, information on the latest Fusion 360 updates, and guided tours to grow your skills in Fusion 360.

Great post Alex – thanks for sharing your experience with Fusion 360. We’re looking forward to you and Brian launching your monthly training sessions with Fusion Fridays.